Efficient quality control has become indispensable due to the ever-increasing quality demands of the processing industry and end customers. Particularly in the processing of metals or plastics, a large number of production errors can occur that run counter to these quality requirements. Reliable and error-free detection of defects, such as cracks in pressed parts, is therefore essential. The detection of these defects can not only lead to a significant lowering of additional costs for subsequent improvements, but also reduce or even prevent the financial loss in the event of committee clear. In addition, a perfectly implemented detection of cracks or other production defects contributes to a significant increase in quality and efficiency.

Quality improvement in production through automatic crack detection

While some industries continue to rely on traditional methods of quality inspection such as visual inspection, other industries have already recognized the benefits of automated quality inspection. In the automotive industry, for example, automatic crack detection not only leads to significant efficiency gains and quality improvements in production, but also reduces costs.

If the visual inspection is carried out by trained employees, there are numerous aspects that need to be optimized. Even with employees who are usually extensively trained and highly qualified, human visual quality assurance is error-prone, expensive and often too slow to ensure an optimal and efficient production flow. In addition, fluctuations in concentration and the personal condition of the person can make it very difficult to ensure reliable, consistent and objective results.

To avoid these fluctuations in quality inspection, every part produced in the production chain must be analyzed according to the same standards and critical cracks must be detected reliably and quickly. In addition, clear labeling and comprehensive documentation of production defects is of great importance. Automated crack detection can ensure that these quality control requirements are met. In order to achieve a measurable improvement in the existing production process, it should also be possible to implement a fully automated software-based solution in the existing system. For this reason, elunic is developing modern solutions for Industry 4.0 that integrate the detection of cracks with the help of AI as an automated step in production in a cost-efficient and fluctuation-free manner. This avoids the need for time-consuming employee training and errors due to fluctuations in human condition.

Find out now whether your quality inspection can be solved with AI

The crack - a common defect in production

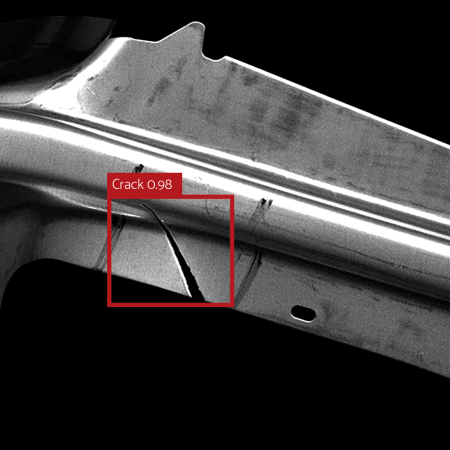

In general, a crack is an imperfection that can occur in a material or the respective end product due to manufacturing or operational causes. If the crack length exceeds a critical threshold, the necessary stability is no longer given and the material breaks along the crack. The worst consequence of cracks is a complete breakage of the material, which is why they are very often described as one of the most dangerous material defects in production.

In particular, the resulting inhomogeneous stress ratio in the vicinity of the crack often leads to significant defects or quality losses such as loss of stability and can result in high costs for reworking in the automotive industry, for example.

Cracks vary in shape, size and severity in many different ways. Regardless of the influencing factors or the appearance of a crack, it usually proves to be an extremely critical defect in production, as even the smallest cracks can become larger over time or through further processing.

However, it is not possible to completely avoid cracks when processing many materials, which is why ways must be found to integrate reliable crack detection into the production process. The aim should be to detect cracks at an early stage in order to counteract their causes in production as quickly as possible.

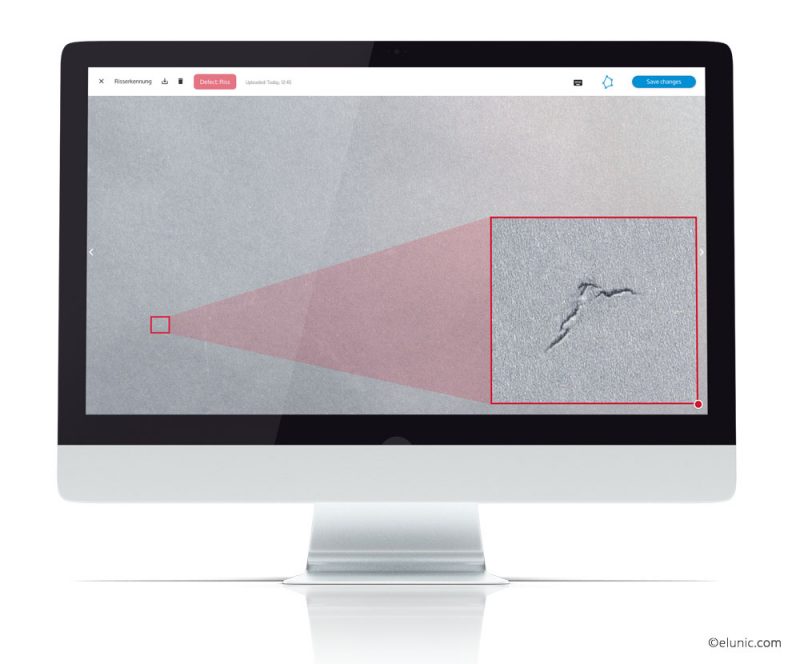

AI.SEE™ - the efficient solution for automatic crack detection

With the automated quality control AI.SEE™ bietet elunic eine speziell für die jeweilige Produktion programmierte Anwendung, die jedes Teil vollautomatisiert analysieren und auf alle Arten und Größen von Rissen oder sonstigen Produktionsfehlern prüfen kann. Durch ihre einfache und äußerst intuitive Handhabung stellt AI.SEE™ die optimale Lösung zur visuellen Qualitätsprüfung aller rissanfälligen Werkstoffe dar, die mit Hilfe von künstlicher Intelligenz Risse zuverlässig erkennt und dokumentiert. Eine umfangreiche Fütterung mit unmissverständlichen Trainingsdaten ermöglicht es, anhand verschiedener Fehlerbilder und Ausschusskriterien ein adaptiv lernfähiges Modell zu erschaffen, das sich ständig weiterentwickelt und so in der Lage ist, auch kleinste Werkstoffrisse zuverlässig zu erkennen. Zusätzliche Fehlerbilder in der laufenden Produktion oder neue Produktreihen können in wenigen Schritten in das System integriert werden. Eine einfache and intuitive Bedienbarkeit der Anwendung stellt hierbei sicher, dass jeder Mitarbeiter in der Qualitätssicherung die Anwendung mit Trainingsdaten füttern kann. Das offene System eröffnet zudem Möglichkeiten für weitere Unternehmensbereiche oder auch externe Dienstleister. Auch diese sind so in der Lage Modelle or Pipelines zu entwickeln und in das System zu integrieren.

Eine umfangreiche Datensammlung und –analyse der cloudbasierten Software ermöglicht eine umfassende Rückverfolgung fehleranfälliger Bauteile und deren Überarbeitung im jeweiligen Produktionsschritt. Neben den Maßnahmen zur Optimierung zukünftiger Produktionschargen bietet die Implementierung einer Echtzeit-Überwachung außerdem zahlreiche Möglichkeiten, um die Ausschusszahlen zu senken.

Interested? Then learn more now about the numerous possibilities for optimal crack detection with AI.SEE™. AI.SEE™!

References

Find out more about the use case.