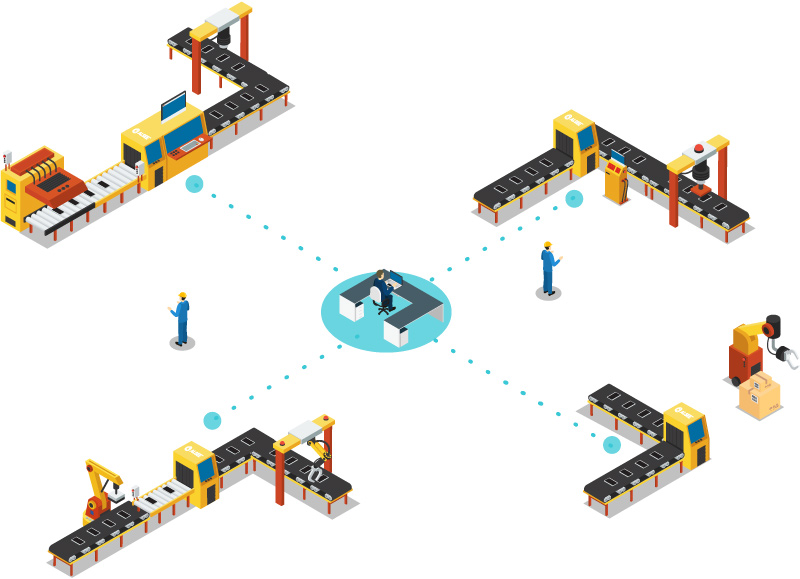

Remote Quality Assurance makes your quality inspection decentralised

In times of digital upheaval, the need to increase efficiency in production and problems arising from issues such as coronavirus and changing hygiene measures, the move towards location-independent quality assurance is essential.

Decentralised quality inspection in the cloud

Traditionally, quality assurance and quality management go hand in hand in the regulation of on-site production. Employees carry out quality control themselves by means of tests and visual quality inspection

One of the new possibilities created by the emergence of Industry 4.0 is remote quality assurance. This allows trained quality management employees to carry out their work from any location. Industrial cameras and sensors in production collect large amounts of data and process it using artificial intelligence. This data can then be analysed locally and independently, for example in the home office. However, the decentralised backup of information in the cloud not only offers the advantage of location independence. It also improves the security of your valuable internal production data.

Remote quality assurance thanks to AI.SEE™

AI.SEE™ from elunic uses artificial intelligence to enable manufacturers to inspect their products reliably and automatically, regardless of location. Thanks to deep learning, even the smallest defects on heterogeneous or reflective surfaces that human inspectors often overlook can be found with consistently reliable quality, providing powerful insights that contribute to increasing quality and operational efficiency. AI.SEE™ enables your employees to access quality control results and make annotations regardless of their location.

The amount of benefits of remote quality inspection and remote working is obvious. Nevertheless, there is an assumption that the conversion of a production to intelligent quality management is very cost-intensive. AI.SEE™ from elunic is based on standardised hardware, such as commercially available cameras, and achieves success through advanced software. By using AI.SEE™, your quality assurance becomes more consistent, effective and efficient, which also increases the economic potential in the industry.

elunic enables its customers to simultaneously optimise quality control and make it more location-independent. As a result, workers with the best qualifications, no matter where they are in the world, can achieve the optimum for their production in their individual, best possible environments. Remote working thus achieves flexibility for developers and quality inspectors.

Advantages

Features

- Image annotation

- Projects and user rights

- Neural networks

- Dashboard and analyses

- Interfaces for imaging systems

- Interface for deployment

- System integration interfaces

Image Annotation

In AI.SEE™ Control, individual images can be inspected in detail, annotated and assigned to defect classes. In addition, images can be managed in sets and assigned to projects so that they can be used for training and retraining various deep learning models.

Projects and user rights

Individual projects can be managed and analysed in the AI.SEE™ project database.

Personalised access to functions, projects and elements within AI.SEE™ can also be defined for users.

Training, deployment and evaluation of neural networks

AI.SEE™ trains neural networks to recognise errors in the background. If faults or components change, AI.SEE™ Control can adapt to this and enables a seamless transition between individual product groups. Neural networks are trained, deployed and evaluated in the system.

Dashboards and analysis

Image, error and training data can be managed on clearly organised dashboards and results can be viewed. Statistics and trends can, for example, indicate wear and tear on production machines at an early stage.

Interface for imaging systems

With AI.SEE™ Lens, elunic provides its own camera and lighting system, but also enables seamless connection to existing systems.

Interface for deployment

Due to the rapid advancement of machine learning technologies, the use of any neural network architecture is possible. Their deployment is possible with the simple implementation of the AI.SEE Engine Interface. AI.SEE™ Engine-Schnittstelle möglich.

Interfaces for system integration in MES / QMS / ...

In order to enable continuous production in a large company, a clear allocation to each production item is necessary. This also includes labelling if a production item does not meet the quality requirements.

Can Artificial Intelligence Automate Your Optical Inspection?

Bei der Unterstützung von Unternehmen in der Produktion treten sehr häufig ähnliche Problemstellungen und Fragestellungen auf. Um Ihnen eine geeignete Abschätzung zur Machbarkeit und Preisvorstellung zu ermöglichen füllen sie bitte den unten stehenden Fragebogen aus.

Find out now with just a few questions whether your problem can also be solved by AI.SEE™.

4 steps to A.I.-supported quality assurance

Step 1:

Proof-of-Concept

1 defect class on a material/product

Start directly and validate your AI-based quality assurance project quickly, cost-efficiently and easily with an online showcase that is able to recognise a defect class on a material or product. Our experts will be happy to support you in finding the right camera system for your solution or in installing our own camera and lighting solution - AI.SEE™ Lens.

Step 2:

Complete online unsecase

All defect classes on all materials/products

In the second step, the project will be expanded and the deep learning model will be further trained to recognise all defect classes on all materials and products from your production and to be able to directly display and analyse the different defect classes for newly uploaded images.

Step 3:

Autonomous installation in production

All defect classes on all materials/products

After your AI.SEE™ project has been trained for all defect classes on all materials or products, you will receive your functioning detection solution on our AI.SEE™ Edge performance computing system optimised for artificial intelligence in order to integrate the image analysis into your production.

Step 4:

Retraining and Remote Quality Assurance

All defect classes on all materials/products

To ensure a high detection rate, AI.SEE™ starts production with a high error sensitivity. In order to reduce the number of error messages to images without errors (false positives) during further operation, false positives are labelled as such during production. AI.SEE™ continues to learn automatically with this data, which reduces the number of false positives on a daily basis.

References

Get in touch.

Do you have a project enquiry or just want to say hello? Don't hesitate to contact us - we will be happy to answer you promptly.