Digital transformation in the industry

As an industrial location, Germany holds a leading position worldwide, but current events such as the coronavirus pandemic also show Germany the scope for development. To do this, companies need to access one of the most important assets of our time: digitalization and data. The digital transformation is connecting people, machines and products, and companies are benefiting from intelligent, precise and efficient work processes.

Areas of digitalization in mechanical engineering

The possibilities for digitizing companies in mechanical engineering are almost unlimited. Software systems in particular can be used in industry to support condition monitoring or maintenance, for example. They draw on important cornerstones of the digital transformation, such as artificial intelligence, big data and cloud computing.

Digital transformation with elunic

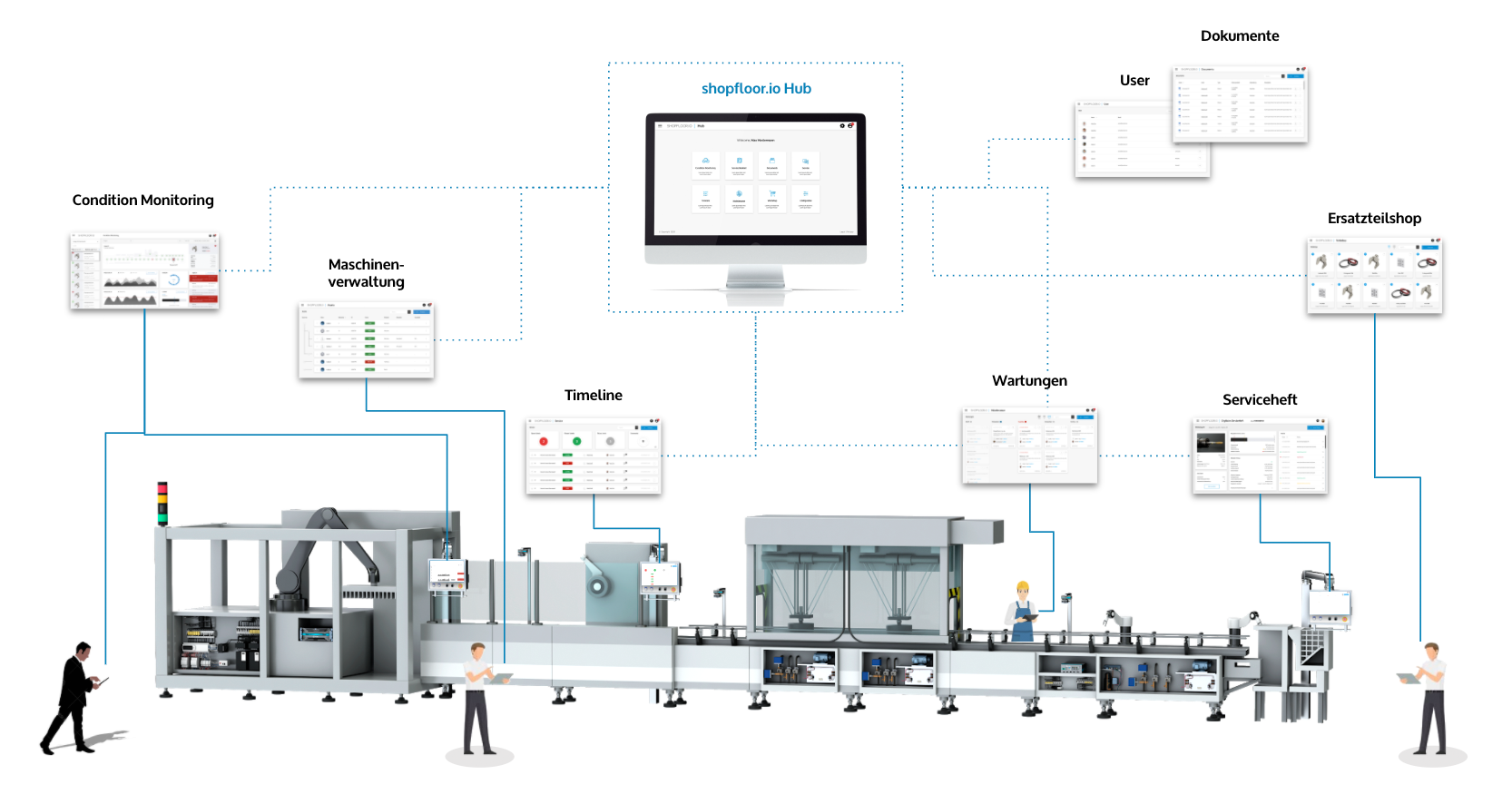

shopfloor.io offers machine manufacturers white-label IIoT applications and software development modules to support their production. The software kit provides machine manufacturers with modules that can be customized and scaled as required. In doing so, shopfloor.io makes use of a major advantage of digitalization: cloud computing. Cloud computing describes the provision of IT resources via the internet and allows companies in the industry to choose whether they want to operate their software on-premises or more flexibly via cloud resources. The implementation of such systems makes companies more flexible and supports them in their growth as required.

New digital resources from shopfloor.io can also be connected to existing systems with interfaces. This creates a networked and efficient workflow within which data does not have to be passed on in analog form, but is available digitally to all authorized persons.

With the individual modules, you can digitize your production either all at once or gradually. While each module runs on its own, you can work in an increasingly networked way by integrating several modules.

But what added value do the modules offer for digitalization in mechanical engineering? Let's take the "Condition Monitoring" and "Maintenance Manager" modules as examples to show the benefits of digitalization in mechanical engineering.

The condition monitoring tool enables digital condition monitoring. Operating and condition data from machines is continuously recorded by sensors, analyzed and displayed in a cockpit. This continuous fine monitoring of the systems provides precise feedback about the machine and therefore quickly identifies anomalies in the system or individual components. On the other hand, the information obtained using the sensors provides data for further digital steps such as predictive maintenance. Big data and artificial intelligence work together to make condition monitoring more effective and reliable.

Ordinary maintenance of machines and systems in industry can also be supported by software such as the Maintenance Manager . The maintenance manager can be used to create and edit inspection dates and maintenance cycles. The reliable documentation of each maintenance task in the maintenance planner software also makes it possible to search, sort and filter maintenance and inspection dates according to status, due date, responsibility or machines and to make this data available to responsible employees in a decentralized manner. In addition to the documentation of inspections carried out and the organization of inspection dates, the maintenance manager provides checklists for the various maintenance tasks. This allows the maintenance of the machines to be checked step by step and individual tasks or the entire maintenance work to be assigned to specific employees.

The two examples show the potential for making production more effective and reliable through digitalization.

Whether artificial intelligence, cloud computing or big data, elunic is your contact for digital transformation and development in mechanical engineering. We support you in implementing new and digital solutions for your company in a tailored and individual way, making you ready for the future in Industry 4.0.

elunic AG: Your service provider

for Predictive Maintenance

Jedes Unternehmen muss sich der digitalen Transformation stellen und den Wandel vom traditionellen Maschinenbauer zum Softwareunternehmen vollziehen. Die Projektsteuerung sollte zum Zwecke des Kompetenzaufbaus intern erfolgen.

However, with an experienced I4.0 service provider like elunic, companies can greatly accelerate their digitalization. They are also supported in their choice of technology and can select the best approach for them from the wide range of possible solutions.

Routinierter Partner für I4.0 &

Predictive Maintenance Projekte

Dozens of medium-sized companies have successfully entered the I4.0 age with elunic. With its 15 years of experience, elunic can also make your digitalization project a success.

Optimally networked with manufacturers and suppliers

I4.0 projects can only succeed in collaboration with manufacturers and suppliers. elunic puts its network at the service of its customers, enabling short decision-making paths and access to best practices.

Strategie und Plattform

aus einer Hand

elunic designs tailor-made I4.0 strategies for its customers. The in-house software platform enables rapid implementation and quick project success.

Showcases

Get in touch.

Do you have a project enquiry? Please do not hesitate to contact us - we will be happy to answer you promptly.