Industrial Internet of Things (IIoT), smart factories and fully networked value chains: The digital transformation continues to make inroads into German industry. But what does it look like in concrete terms? The leading manufacturer of thermoforming, packaging and tooling systems, ILLIG Maschinenbau GmbH & Co. KG, has set itself the goal of actively supporting its customers on the path to Industry 4.0. ILLIG is cooperating with the Munich-based IIoT software company elunic. Together, they have developed the digital service platform "ILLIG Assist" and are taking the next steps in the field of thermoforming towards the fully networked factory.

The fourth industrial revolution continues to gather pace in German companies. Thanks to innovative technologies, the guiding principle of holistic digitalization is increasingly becoming a reality. This also applies to the packaging industry: manufacturing processes are becoming more digital and the entire value chain is being networked. The world's leading supplier of thermoforming and tooling systems demonstrates the potential that can be tapped as a result ILLIG Maschinenbau GmbH & Co. KG.

Communication between user and machine

ILLIG machines are already equipped with intelligent operator support systems, such as a basic setting calculation of the machine parameters, a guided set-up system or dynamic optimizations. They also offer the option of the necessary connectivity and querying of production-relevant data points.

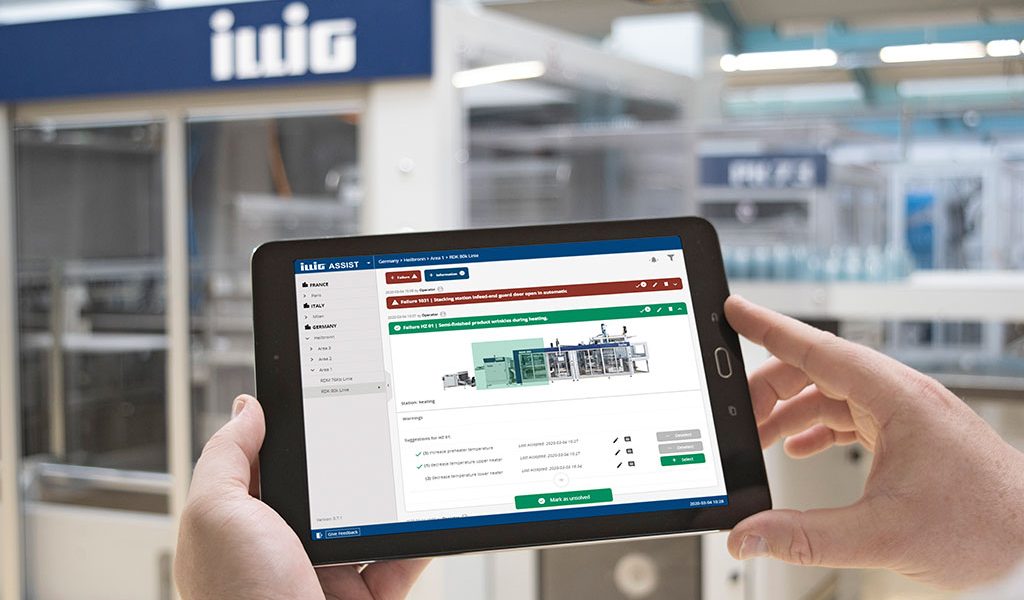

ILLIG Assist supplements these supporting systems and helps the machine operator to eliminate incidents in daily operation. While this was previously based on notes and the personal experience of individuals, the new application simplifies the transfer of knowledge by means of a clear and interactive user interface.

Messages from connected machines as well as from the machine operators themselves are recorded and displayed chronologically. The system automatically provides a visual localization of the event that has occurred and detailed solution suggestions based on a solution database. This is initially created with the knowledge of ILLIG. In addition, operators can actively contribute their own suggestions for dealing with recorded system messages and enrich them with videos and images, for example. An integrated chat function makes it possible to comment on and evaluate suggested solutions. This system serves to build up a permanent knowledge database, prevents loss of knowledge due to the departure of experienced machine operators and accelerates the training phases of new employees on the systems. ILLIG Assist bundles the experience and knowledge of operators and makes it available to all users. Users can also view and manage shift reports, maintenance information and digitally prepared manuals, for example.

ILLIG Assist is based on an IIoT platform. Events that are reported to ILLIG Assist can be displayed with any internet-enabled communication terminal and operators can be informed on the move. The event messages are sent by the operator or, in future, directly by the machine in the case of networked machines connected to the IIoT platform. Based on the IIoT platform architecture, the messages are automatically made available to other approved users within the organization. In addition to the asset management and chat function for each machine, ILLIG Assist also provides rights management for creating and reading comments and other information. Depending on a user's rights, the system provides insight into the machine with its functional sub-blocks as well as an overview of the entire line, factory or worldwide locations. Third-party machines can also be easily integrated, even if they do not yet offer any digital interfaces themselves.

Implementing customer benefits in an agile way

When developing ILLIG Assist, the focus was clearly on the benefits for machine operators and production managers, with the aim of increasing efficiency in production, service and maintenance through an intelligent store floor communication tool and active knowledge management.

As the requirements could deliberately only be roughly specified at the beginning, the agile project management method SCRUM was used in collaboration with the Munich-based IIoT software company elunic in an iterative approach. The deliberate aim was to evaluate progress based on real user feedback and to integrate iteratively. ADAMOS was chosen as the IoT platform.

ILLIG Assist, das durch eine Architektur bestehend aus Microservices modular erweiterbar ist und eine flexible Anbindung an externe Systeme ermöglicht, bildet die Grundlage für die IIoT-Strategie des Thermoform-Maschinenbauers.

Aktuell ist ILLIG auf der Suche nach Leadkunden, die bereit sind ILLIG Assist in Ihrer Produktion im Livebetrieb zu testen.

About ILLIG GROUP

ILLIG is a leading global supplier of thermoforming systems and tooling systems for plastics. The range of services includes the development, design, manufacture, assembly and commissioning of complex production lines and individual components. With its 360° packaging development Pactivity® and high-performance packaging systems, ILLIG offers its customers resource-efficient and sustainable solutions, "Designed4Recycling". With its own subsidiaries and agencies in over 80 countries, ILLIG has a local presence in all markets around the globe. For over 70 years, the family-owned company has supported its customers worldwide as a reliable partner in the economical production of sophisticated and high-precision molded parts made of thermoplastics - with innovative technology of the highest quality and comprehensive global service.

Note: Terms marked with ® are registered and protected trademarks of ILLIG Maschinenbau GmbH & Co.

Further references

More about the reference project.