Wir bieten maßgeschneiderte Lösungen für die Qualitätssicherung in der Produktion, die die Geschwindigkeit und Präzision in der Bildverarbeitung maximieren. AI.SEE™, bestehend aus dem AI.SEE™ Core und dem AI.SEE™ Line Inspector, ermöglicht eine automatisierte Fehlererkennung für jede Fehlerklasse oder Bauteil. Dabei passt sich das System an Ihre spezifischen und gegebenenfalls vorhandene Systeme an und gewährleistet eine eine nahtlose Integration in Ihren Prozess.

AI.SEE™ Features

- Image annotation

- Projects and user rights

- AI training

- Dashboards and analysis

- Interface for imaging systems

- Interface for deployment

- Integrations

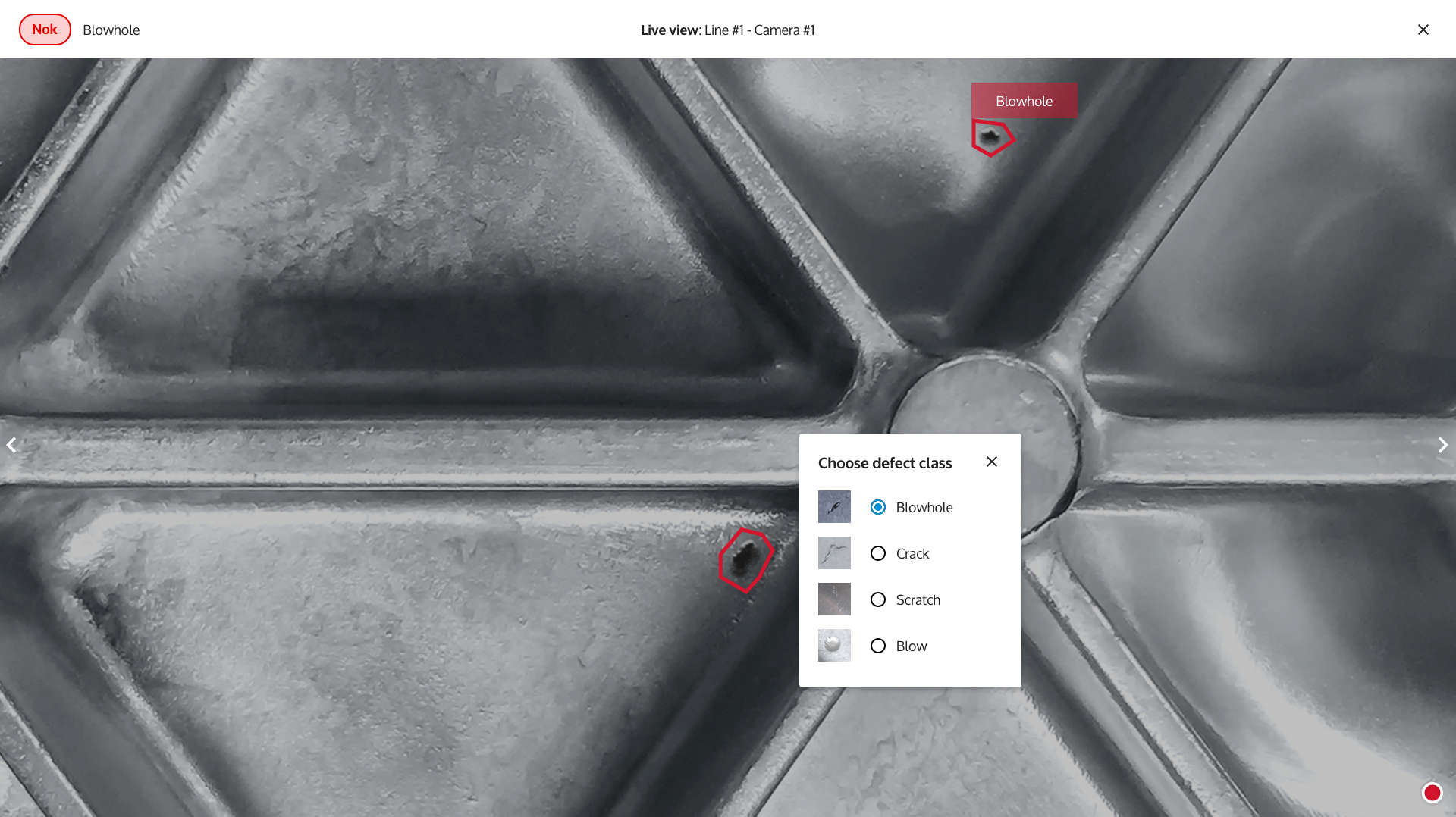

Image Annotation

AI.SEE™ Core, individual images can be inspected in detail, annotated and assigned to defect classes. In addition, images can be managed in sets and assigned to projects so that they can be used for training and retraining various deep learning models.

Projects and user rights

Individual projects can be managed and analysed in the AI.SEE™ project database.

Personalised access to functions, projects and elements within AI.SEE™ can also be defined for users.

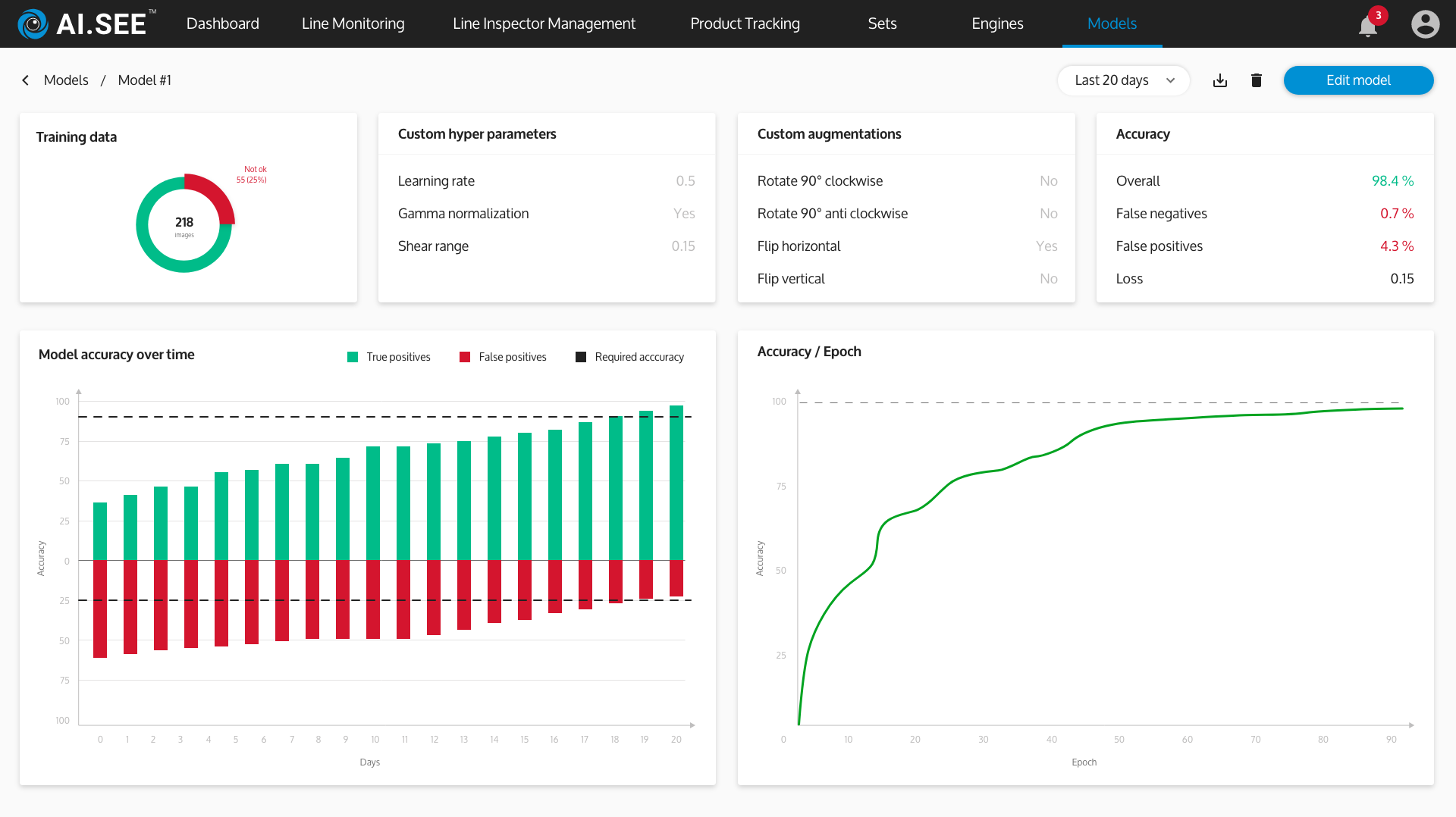

Training, deployment and evaluation of neural networks

AI.SEE™ trains neural networks to recognise errors in the background. If faults or components change, AI.SEE™ can adapt to this and enables a seamless transition between individual product groups. Neural networks are trained, deployed and evaluated in the system.

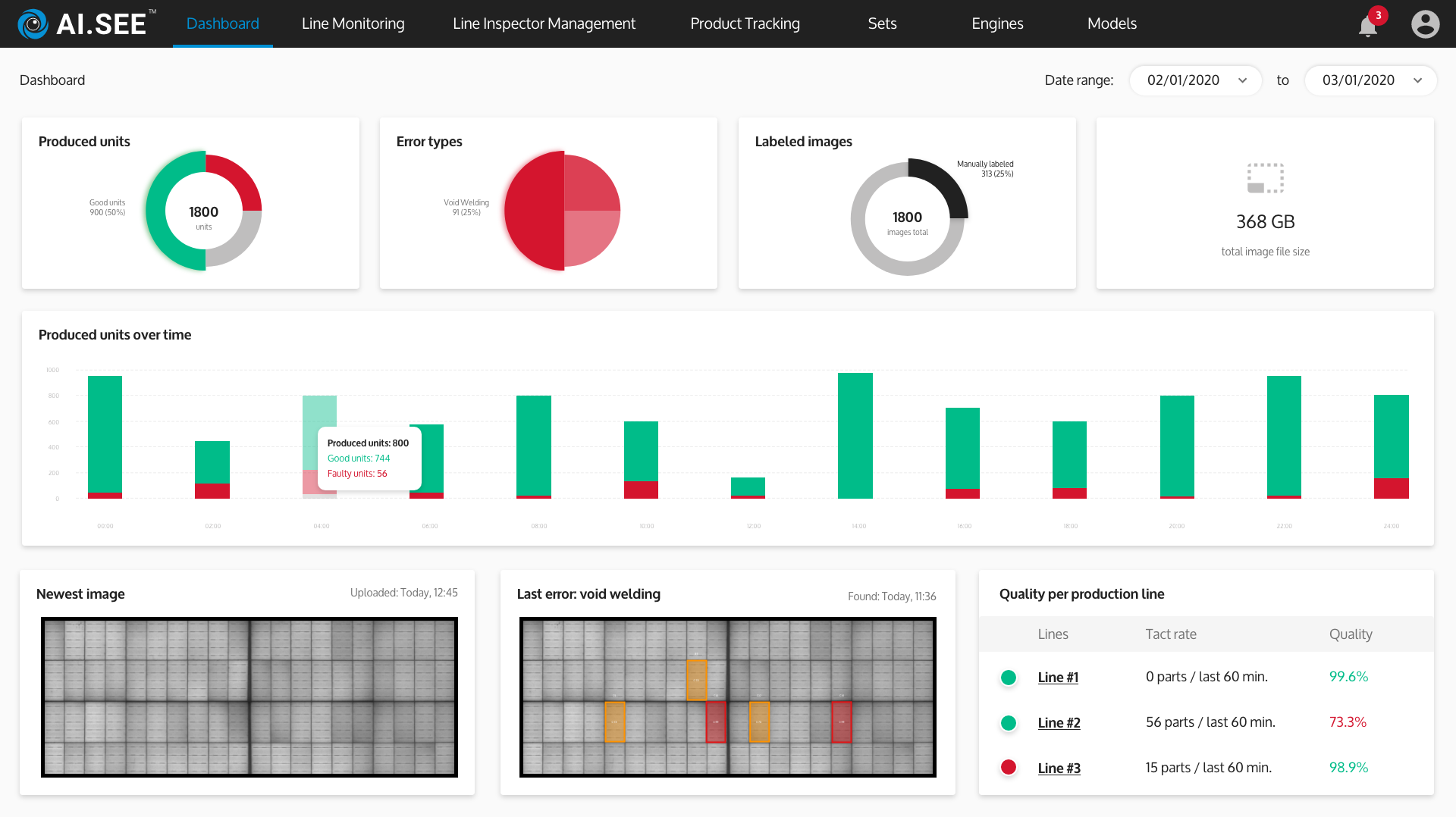

Dashboards and analysis

Image, error and training data can be managed on clearly organised dashboards and results can be viewed. Statistics and trends can, for example, indicate wear and tear on production machines at an early stage.

Interface for imaging systems

We provide our own camera and lighting system, but also enable seamless connection to existing systems.

Interface for deployment

Due to the rapid advancement of machine learning technologies, the use of any neural network architecture is possible. Their deployment is possible with the simple implementation of the AI.SEE Engine Interface. AI.SEE™ Engine-Schnittstelle möglich.

Interfaces for system integration in MES / QMS

In order to enable continuous production in a large company, a clear allocation to each production item is necessary. This also includes labelling if a production item does not meet the quality requirements.

State-of-the-art AI software

AI.SEE™ Core

With AI.SEE™ Core, you collect and manage large volumes of quality assurance data and images. AI.SEE™ automatically trains the AI-assisted, self-learning, neural-network-based error-detection algorithm, further improving its accuracy with every new image.

Highlights

Your eyes on the production line:

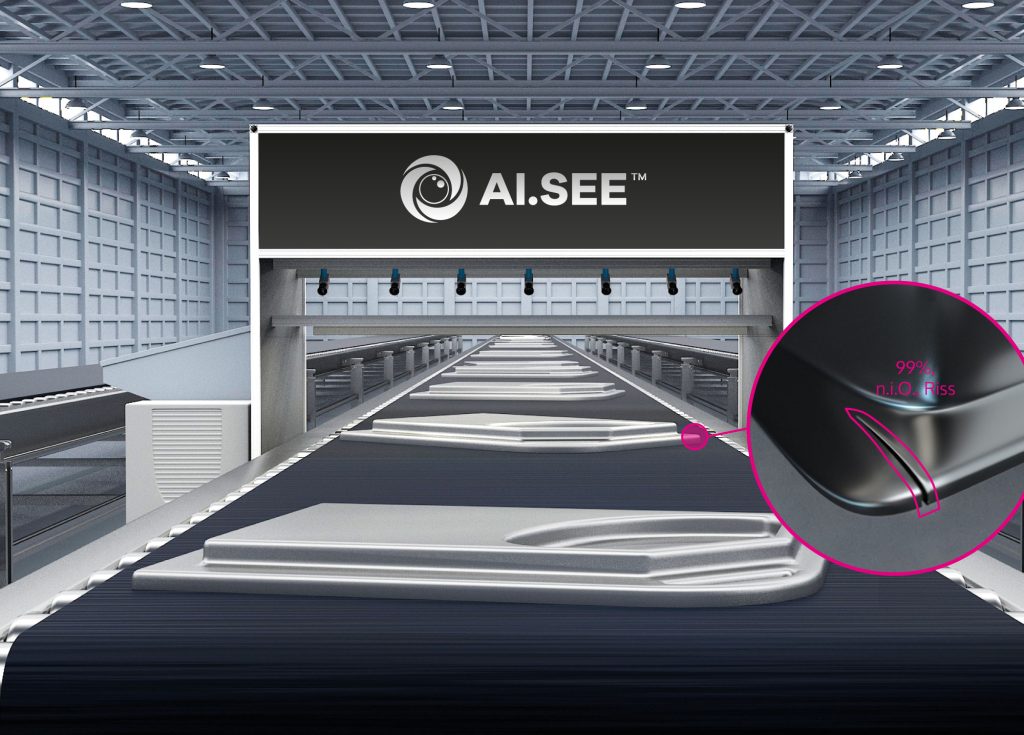

AI.SEE™ Line Inspector

The AI.SEE™ Core is expanded by the AI.SEE™ Line Inspectors - smart cameras and AI analysis tools that are installed per line and managed via the AI.SEE™ Core. The Line Inspectors analyse the incoming images on the line and control further processes.

Our Customers

Get in touch.

Do you have a project enquiry or just want to say hello? Don't hesitate to contact us - we will be happy to answer you promptly.