Wir begleiten Sie bei der Vernetzung mit ihren

ausgelieferten Maschinen und Betreibern

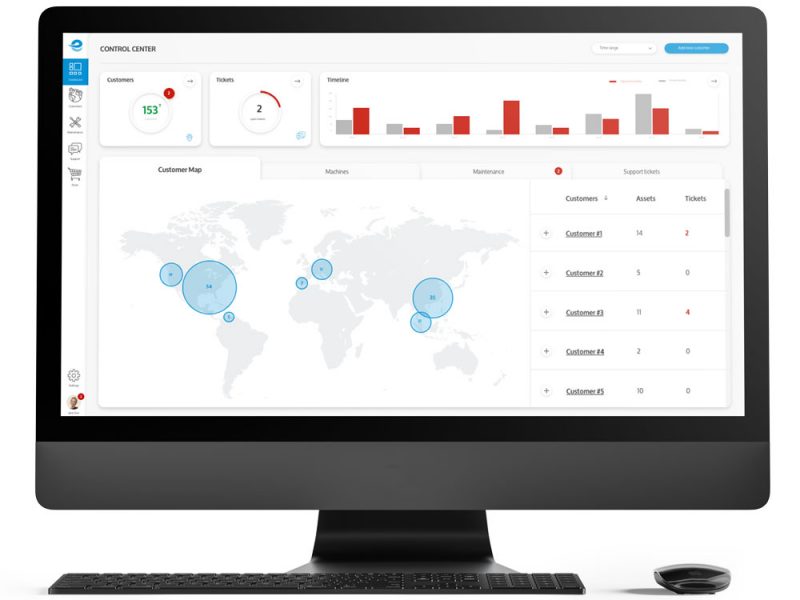

Remote condition monitoring baut durch Echzeit-Zustandsüberwachung Software ausgelieferter Maschinen kundenübergreifendes Prozesswissen auf, das Ihnen hilft Ihre Produkte und Ihren Service weiterzuentwickeln sowie Verfügbarkeiten sicherzustellen.

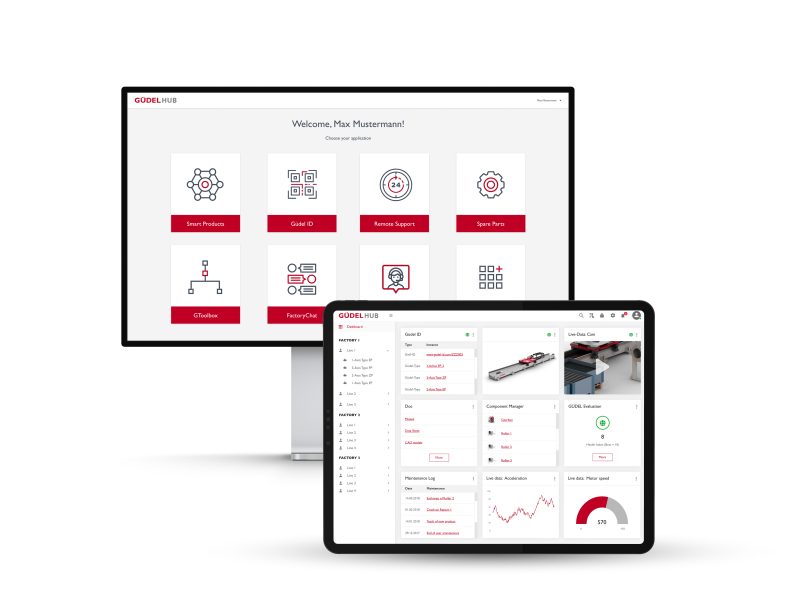

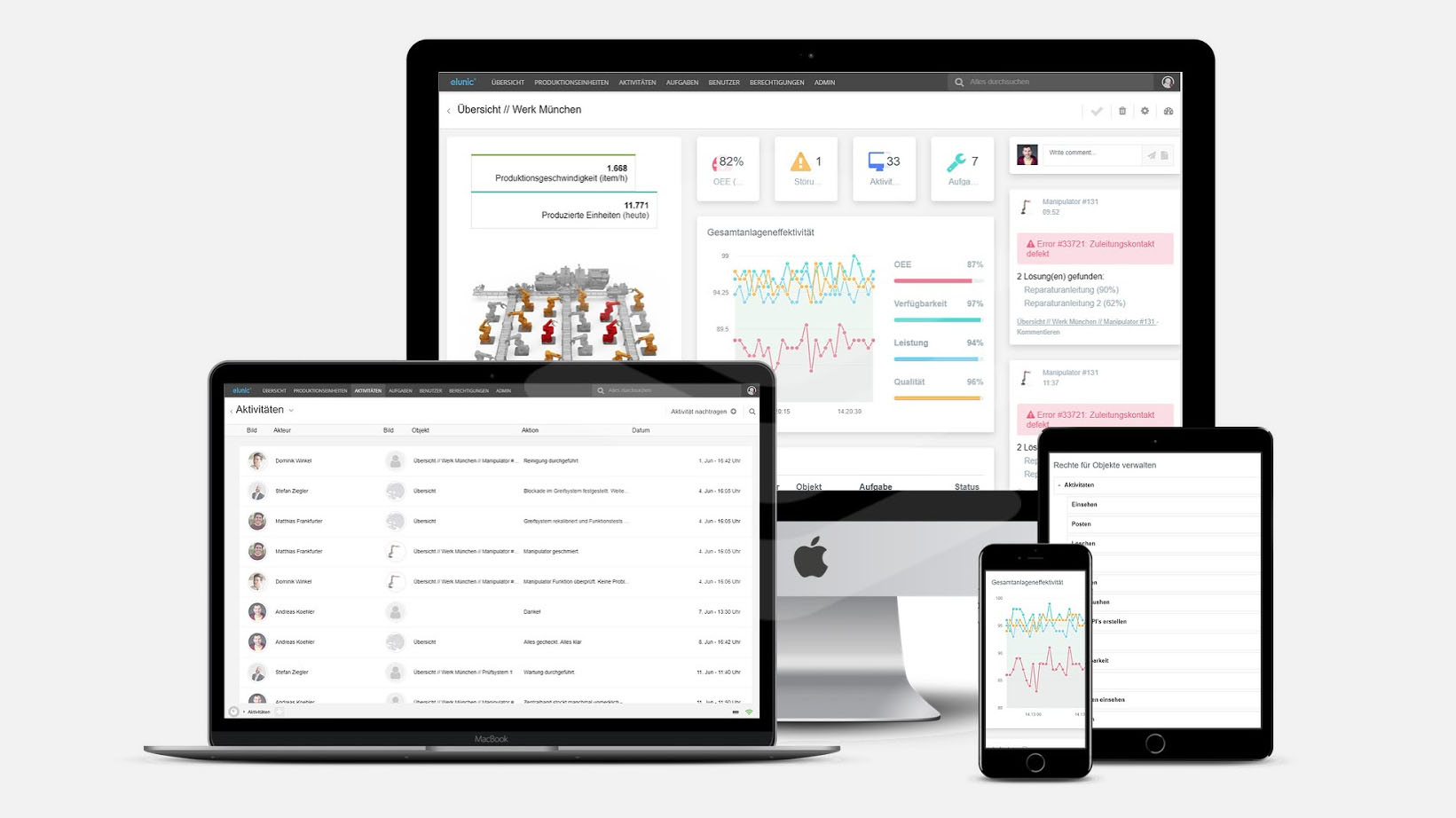

Condition Monitoring für den Maschinenbau, also die smarte Condition monitoring from elunic wird durch Module des shopfloor.io – Industrie 4.0-Softwarebaukastens ergänzt, mit dem Maschinenbauer über ein passgenaues Whitelabel-Maschinenportal ihre Maschinen und und Mitarbeiter vernetzen und durch Sensoren erschlossene Daten schnell und übersichtlich visualisieren können.

- Establishment of a return channel from the customer

- New insights into machines in the field

- Precise findings and recommendations for action

- Proactive troubleshooting

Close the gap between you and the machines you sell by consistently tracking the condition and use of your machines at the customer's premises. With remote condition monitoring, you create a feedback channel from the customer to influence what happens after your machines have been sold. This enables you to move from reactive to proactive action.

- Faster response time

- Lower service costs

- Higher customer satisfaction

Use new efficiency levers to counteract the exhausted optimization potential of your machines. Remote condition monitoring gives you a connection to the customer at any time and any place. This shortens the process for better customer service at lower costs.

- Development of cross-customer production knowledge

- Digital, data-based services

- Consistent further development of the machines

- Basis for predictive maintenance

Remote condition monitoring creates the data basis for gaining important insights for product development as well as for building digital business models. Business-relevant actions are initiated on the basis of facts and the risk of wrong decisions is minimized. By generating a broad database across not just onebut all customers, services such as predictive maintenance become feasible.

Remote Condition Monitoring für Ihr Unternehmen

Remote Condition Monitoring Software Features

Remote Condition Monitoring draws on proven concepts and established algorithms of the condition monitoring module of the shopfloor.io software suite and can be expanded as required.

- Condition monitoring

All data can be accessed at any time on any end device - in real time. A detailed system analysis detects anomalies and automatically triggers alarms. Use the data to get to know your delivered machines better.

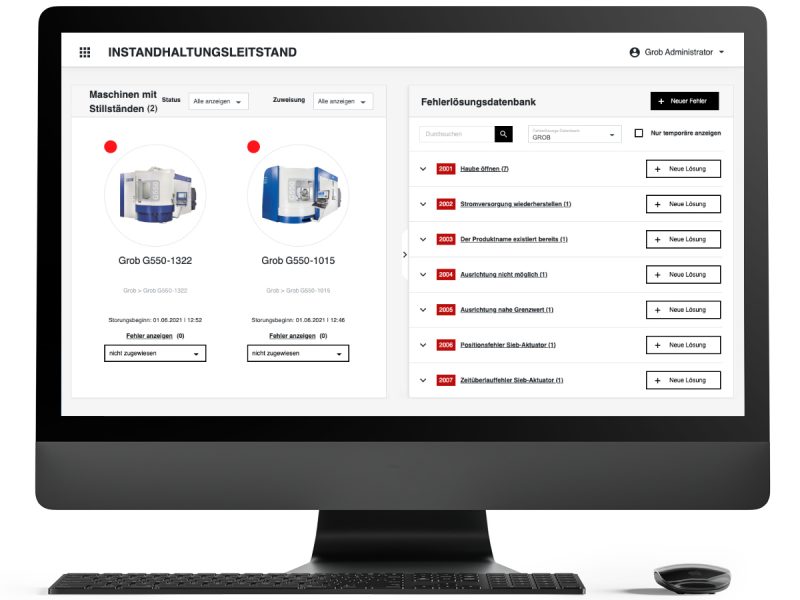

- Machine management

Manage customers, plants, lines and machines - all in a clear hierarchical structure. Store all Informationen und Dokumente.

- Personalized dashboards

Visualize all relevant key figures and KPIs. Thanks to the software's intuitive operation, you have an immediate overview of the most important information. The open interface gives your customer flexibility for individual evaluations.

- Knowledge and document management

Set up a digital knowledge base and provide your customers with a digital overview of all documents. The software links these directly to error messages as suggested solutions. In addition, digital, interactive training material enables an efficient learning process.

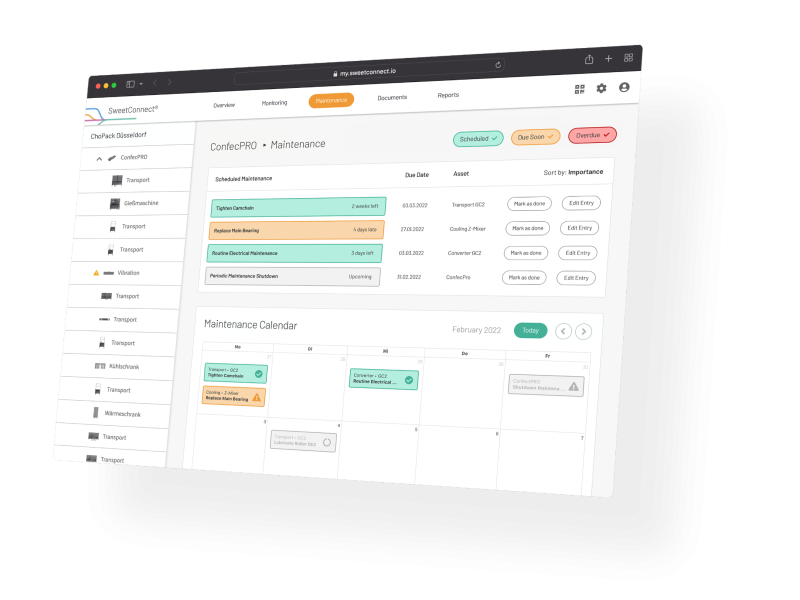

- Maintenance and servicing

Bieten Sie Ihren Kunden einen Remote Support durch Echtzeit-Störmeldungen und automated Wartungsaufgaben. Handeln Sie proaktiv um Ihren Kunden einen bedarfsgerechten Service zum richtigen Zeitpunkt liefern zu können.

Remote Condition Monitoring in der Industrie 4.0

Added value Industry 4.0 and networking in mechanical engineering

5 steps to a successful start in condition monitoring for mechanical engineering

A remote condition monitoring project must be thought through from start to finish in order to gain a real competitive advantage. Our guide shows you the specific steps you need to take in order to exploit the potential of your project with five recommendations for successfully getting started with condition monitoring.

Get in touch.

Do you have a project enquiry? Please do not hesitate to contact us - we will be happy to answer you promptly.