How AI-based image recognition is changing quality assurance

The Image recognition (Image Recognition) offers new possibilities for image-based quality assurance. For the first time, it is easy to recognise objects under difficult circumstances and from changing angles. Despite shadows, lighting effects or patterned image backgrounds, objects can be reliably identified using image recognition. With conventional image processing (computer vision), none of this is possible, or only with great effort. In addition, image recognition systems can be set up more quickly than conventional image processing methods.

Successful recognition through machine learning

The decisive factor for more flexible visual analysis through image recognition is the use of artificial intelligence. In contrast to image processing, image recognition is not based on pre-programmed rules, such as the shape, number or position of objects. Instead, the computer learns to identify objects by common characteristics, similar to a human being, through image examples.

For example, a person recognises screws regardless of their position, size, head shape and thread length. Humans also recognise special screw shapes such as grub screws, knurled screws and screw hooks as screws. An AI system can use machine learning to achieve a recognition rate almost as high as that of a human. All it takes is to analyse a sufficient number of images of screws of different types. The AI then recognises which objects belong to the "screw" type.

Execution even under difficult circumstances

Machine learning can also be used to train a computer to distinguish objects from shadows and backgrounds. This property allows AI-based image recognition analyse unstructured images and live videos in which the objects have not been positioned uniformly. People do this unconsciously. However, this is a difficult obstacle to overcome for simple image processing.

Typical applications of image recognition in industrial quality assurance include, for example

- Surface inspection

- Measurement of sizes and shapes

- Completeness check

- Object recognition

- Location and position detection

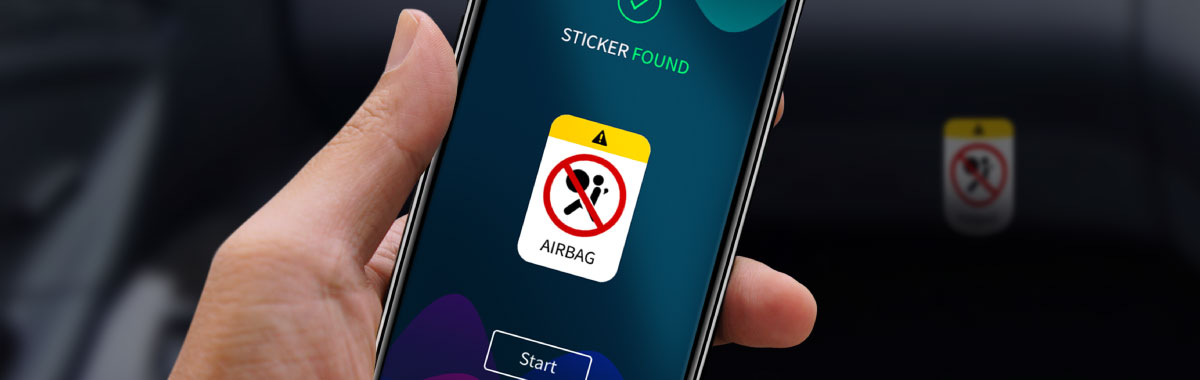

For example, one car manufacturer is using AI-based image recognition in a pilot project to check whether a cover for the headlamp levelling has been installed correctly. Such a component is mandatory for all cars exported to the USA. One problem is that this component is shaped differently depending on the vehicle. It is also the same colour as the cockpit trim and hardly stands out visually. The AI system has no problems with this requirement and even manages with fewer high-resolution cameras than conventional vision systems.

Required hardware available at low cost

The principle of image recognition using AI has been known in research for some time. However, it is only in recent years that this technology has become affordable for industrial applications such as quality assurance. The main reason for this is rapid progress in hardware. Today, processor units designed for AI with hundreds of computing cores ("tensor cores") are available. With prices in the low to mid four-digit euro range, the cost of the hardware is no longer a major obstacle.

High detection rates after a short time

The development of software is also easier for AI-based image recognition systems. This is because the image recognition algorithms remain the same. They are simply fed with sample images for new inspection tasks, with a human tutor evaluating the images. Depending on the task, the test objects can be displayed from different angles and against different backgrounds. As the example of the light cover for export cars shows, differently shaped objects can belong to the same object category. The car manufacturer achieved a recognition rate of 95 per cent after just a short period of training the AI. And this continues to improve with ongoing training by tutors.

Images or videos of the test objects are often already available from the test systems to be replaced or can be generated with little effort. It is then important to productively utilise this treasure trove of data for the company. Take advantage of the opportunities offered by image recognition using AI.

Read more: AI.SEE - Visual quality control and error detection system