Anomaly detection for machine manufacturers

Detecting anomalies is an important step for machine manufacturers to ensure production quality. Whether through control or limit value-based solutions or with the help of artificial intelligence - those who recognize anomalies quickly can reduce and avoid errors, production defects and wear. With the help of AI-powered systems, machine manufacturers can automate the anomaly detection of their machines and provide their customers with greater efficiency and reliability of their systems.

Automated anomaly detection

through artificial intelligence

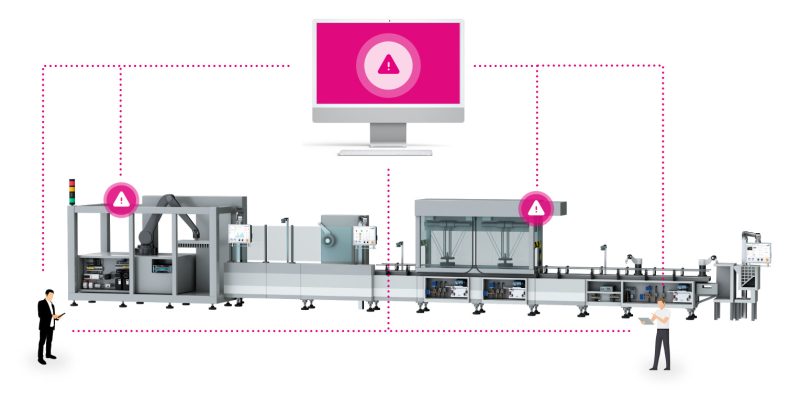

Thanks to the IoT technologies implemented by elunic, machine builders can provide their customers with the benefits of machine learning-driven anomaly detection on an intuitive user interface without any data science expertise. Intelligent sensors record, analyze and annotate data about each individual system component in real time and create machine learning models. These models detect equipment wear and tear, such as component wear and process problems (e.g. temperature fluctuations) and can be linked to other service offerings, such as maintenance and service management software or spare parts stores.

The trained machine learning models enable operators to track anomalies via their own interface, create further annotations or train their own models for other use cases in self-service. By setting up individual notifications, the producer can be informed quickly and in good time about deviations in machine usage at any time and thus counteract problems such as machine damage and subsequent downtime. Furthermore, the self-created use cases and models provide the machine manufacturer with a feedback channel with valuable information.

Alle Vorteile auf einen Blick

Anomaly detection module features

Request a non-binding quote now

Reference projects

Solutions realized with shopfloor.io building blocks

The shopfloor.io software modules help machine manufacturers to quickly get started with the development of customized Industry 4.0 solutions. shopfloor.io provides individual software modules for cloud or on-premises operation and is used as the cornerstone of a scalable and secure IIoT system architecture with which machine manufacturers can network their systems and employees in a machine portal and clearly visualize tapped data or connect it to their existing structures.

Further shopfloor.io modules:

Contact us.

Do you have a project enquiry or just want to say hello? Don't hesitate to contact us - we will be happy to answer you promptly.