There are different quality requirements within industrial production chains. Various influences during production lead to the manufacture of defective products that do not meet these requirements and therefore require subsequent sorting. Optimized industrial image processing can make a significant contribution to preventing the costs incurred.

Conventional optical quality assurance

Traditionally, visual quality control is carried out by trained employees without automatic image processing and cameras. The human brain is able to transfer its comprehensive and complete understanding of industrial quality requirements to the product and intuitively and correctly decide between "flawless" and reject in the event of a deviation.

For cost reasons, however, it is almost impossible to have every part produced in series production checked individually by a quality assurance employee without relying on automated image processing. The results of the quality inspection and therefore the quality within the production chain fluctuate depending on the employee's daily form. In addition, traditional optical quality assurance by a person does not allow every step of production to be reliably checked and recorded. This is why modern industrial production facilities rely on image processing software.

Automated visual inspection with computer vision

In addition, in the course of globalization, increasing cost pressure and maintaining competitiveness are cited as key factors for the progressive replacement of trained personnel by automated quality controls. Machine vision based on rule-based computer vision systems in particular has proven to be extremely effective.

Increasingly powerful camera systems for the identification of production defects have meant that human capabilities can be significantly outperformed by image processing in terms of measurement accuracy and speed. This increase in efficiency helps companies in various industries to keep pace with global competition and meet the increased quality requirements of their customers.

Existing threshold and limit values in the industry, such as standards, also mean that automated quality assurance systems are better suited to image processing than human optical production control. In addition, decisions made by camera systems and sensors for image processing can be tracked within the production chain. This makes industrial image processing a significant added value when optimizing or converting the production chain.

Find out now with just a few questions whether your problem can also be solved by AI.SEE™.

Limitations of industrial image processing

However, the greatest challenge in image processing is the integration of this automation technology. Lighting, working position, camera perspective, object background etc. must be just as homogeneous as the objects to be inspected and their surfaces. In order to ensure this necessary homogeneity for image processing, the camera systems are often equipped with corresponding chambers, which leads to costliness and loss of usable production space. Furthermore, each product requires a decision tree that is uniquely tailored to image processing and is usually complex. This makes these expert systems powerful solutions only for very specific requirements. This is referred to as an "island talent".

This leads to potentially problematic restrictions in the automated Quality control.

For example, a specific condition for pattern recognition the image processing could be incorporated into a rule-based computer vision system. This ensures quality assurance under the existing conditions. However, if conditions such as lighting conditions, reflection and shadows change, the system can no longer make reliable judgments. This means that production errors can go unnoticed and production costs can skyrocket. A reliable assessment of product quality can only be made by a trained employee. They have a broad range of prior knowledge about the natural framework conditions, which qualifies them for quality assurance in production.

The industrial quality assurance system must therefore be equipped with comparable capabilities in the course of the desired increase in efficiency and cost reduction through automatic image processing.

Visual industrial image processing software 2.0

AI-based industrial image processing can ensure this.

The principle of machine learning based on examples, automation and hierarchical feature extraction, collectively referred to as deep learning, forms the basis of image processing.

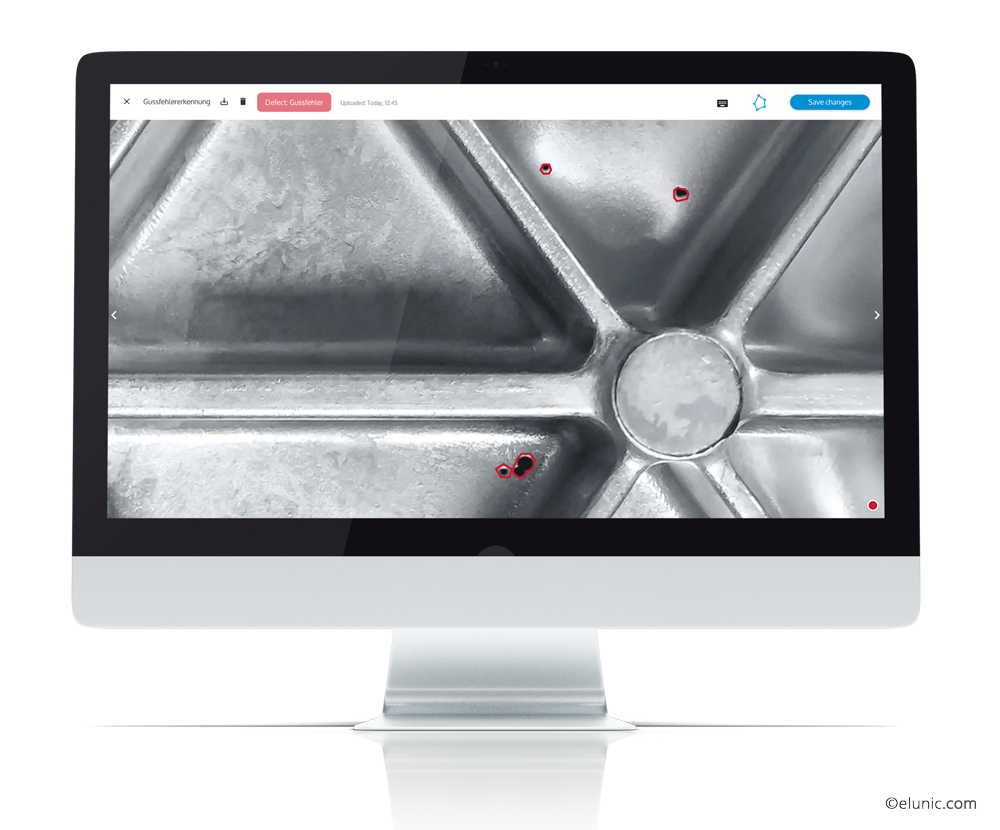

Inspired by the learning of the human brain, image processing software for automatic image evaluation can learn and recognize additional and changing defect images using deep learning algorithms. For this purpose, complex artificial neural networks are trained using many sample images tailored to the respective quality control and their individual specifications in order to meet the respective production standards.

Neural networks specially "pre-trained" for the respective industry significantly reduce the required number of sample images and make it easier to get started with automated quality assurance using image processing software. The identification of production errors by automated industrial image processing systems thus achieves a level of human accuracy and reliability during implication while maintaining industrial speed standards.

Camera systems and sensors driven by image processing software can be integrated cost-effectively into the production chain and enable space-saving and efficient quality controls using industrial image recognition and automated image processing.

Industry 4.0 relies on automated image processing

This advanced technology of image processing systems is a decisive point in the modernization of production lines through image processing.

Due to the ever-increasing globalization of the world market, it is essential to equip a production facility with the latest technology. The emerging Industry 4.0 benefits greatly from "intelligent technology" such as optimized industrial image processing. However, Industry 4.0 does not always mean the latest and most expensive technology. Rather, Industry 4.0 means "connected industry": intelligently optimized processes and adaptive systems that can lead to cost reductions. At the same time, they offer further opportunities for optimization.

This sounds like a cost-intensive investment, especially in industrial image processing. However, the highly specialized software makes it possible to use standardized camera systems without great effort. This ensures worry-free "in-line" integration of the image processing systems into the production line.

Industry 4.0 therefore holds enormous potential. However, image processing using machine vision systems is not the only area in which artificial intelligence can be used. There are also many other solutions from elunic for your entry into Industry 4.0 - find out more now!

elunic is already using the combination of automated image processing and deep learning very successfully in many applications. AI.SEE™ combines the intuitive concepts of human understanding with the advantages of advanced industrial automation technology.

Showcases.

More machine learning services from elunic

Get in touch.

Do you have a project enquiry? Please do not hesitate to contact us - we will be happy to answer you promptly.