Strategy consulting and software integration for Manufacturing IoT (IIoT) & Industry 4.0

What is Industrial IoT (IIOT) and Manufacturing IoT?

The Industrial Internet of Things (IIoT) is the industrial version of the Internet of Things (IoT), in which objects and machines are networked and independently exchange and process information with each other. IIoT is usually referred to as Industry 4.0 and machine-to-machine communication (M2M).

IIoT simplifies processes and increases their efficiency in order to reduce costs while speeding up production.

KI & IoT Consulting und Softwareintegration für Manufacturing IoT (IIoT) & Industrie 4.0

elunic is an AI & IoT service provider that develops AI & IoT software solutions and microservices for Industry 4.0. Through our years of expertise and our team of highly qualified and specialized experts, elunic has established itself as an AI & IIoT software developer and strategy consultant in Industry 4.0: We offer you AI & Iot consulting and AI & IoT solutions from a single source!

AI & IoT Consulting discovers untapped AI & IoT potential

AI & IoT Consulting helps you to fully exploit the development potential of AI & IoT in your company and to plan and effectively implement successful AI & IoT implementations. We support you in AI & IIoT consulting with the development of suitable AI & IoT strategies, the identification of suitable AI & IoT solutions and the implementation of entire IoT systems. By choosing the right technology, you can improve operational efficiency and productivity in your business by automating operational processes and monitoring your assets automatically. Our AI & IoT Consulting will further show you how you can realize cost savings through the use of innovative AI & IoT solutions by monitoring and controlling your plants, machines and processes more effectively through the collection and analysis of real-time data. Other benefits that we will convince you of in our AI & IoT consulting include increasing efficiency, improving customer loyalty, opening up new business opportunities, improving process reliability and, of course, increasing your competitiveness!

For our work in AI & IoT consulting and as a system integrator, we are constantly adapting to new developments and working with the latest technologies in order to present and implement the best possible results for our customers. In our role as an AI & IoT service provider, we support you in your AI & IoT decisions and create individual software and AI & IoT solutions for both large and small companies as part of our consulting services and provide information on the various possibilities of digital transformation.

One of the biggest challenges when implementing AI & IoT solutions is the integration of different plants, devices, machines and systems that work with different technologies and protocols. Our consulting team has a deep technical understanding and years of experience in integrating different AI & IoT devices and systems to ensure seamless and effective collaboration.

Softwareintegration, Rollout and Change Management

As an AI & IoT service provider, we support your project from concept development through to implementation, so that the end result is a product that meets your requirements. The changeover to new software does not always go smoothly, as many employees in companies have concerns about changeovers and modernizations. With our rollout strategies, we take preventative action to counteract negative sentiment and create a positive attitude. It is important to convince as many employees as possible of the benefits of digital transformation. Better communication and collaboration can only be achieved by digitally connecting all elements in your company.

Digitalization is an ongoing process that many companies will face sooner or later. We accompany you in this process, help you to master these challenges and accelerate the digital transformation as an AI & IoT service provider with the help of expertise, knowledge and individual solutions.

Start the digital transformation of your company and exploit the full AI & IoT potential of your machines with tailor-made applications. Get in touch with us now!

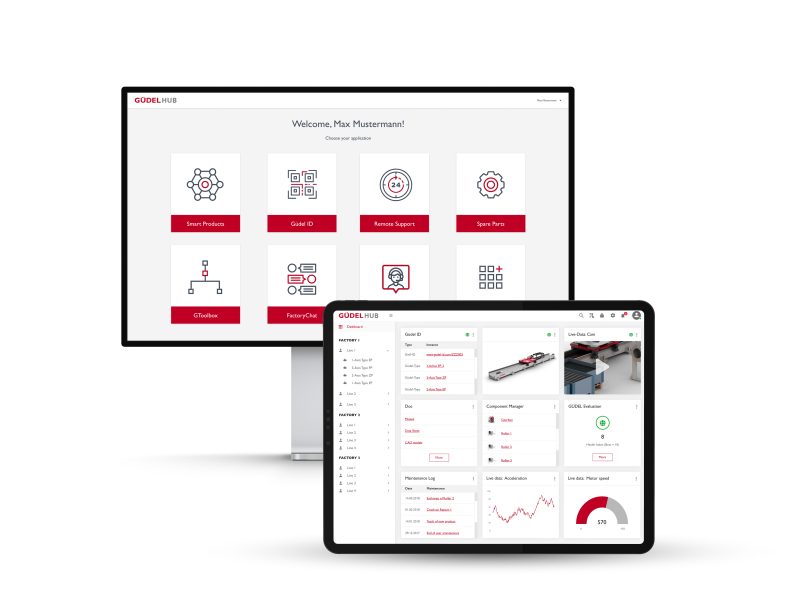

Digital services & digital twin

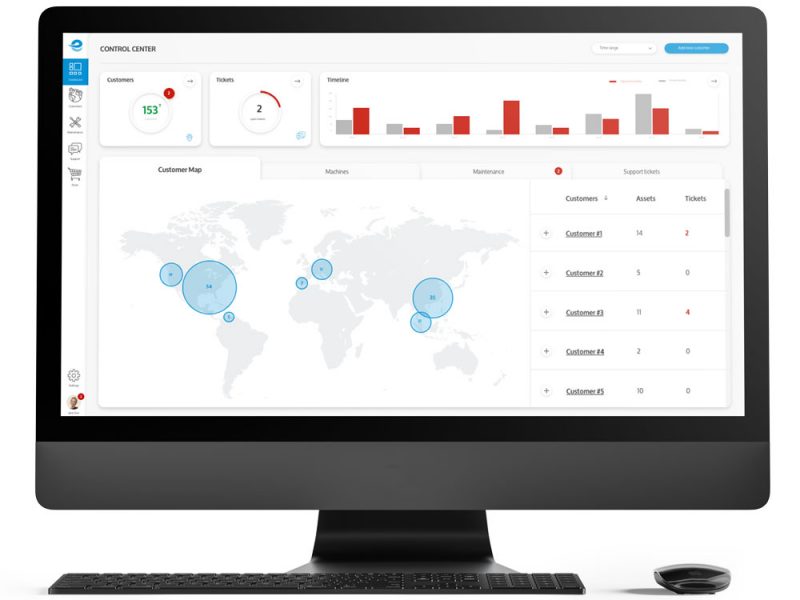

Digital services increase the competitiveness of your products and strengthen customer benefits and loyalty. Usage data is worth its weight in gold, as it enables individual advice, needs-based upselling and predictable maintenance. We advise you and work with you to develop innovative and future-proof user experiences.

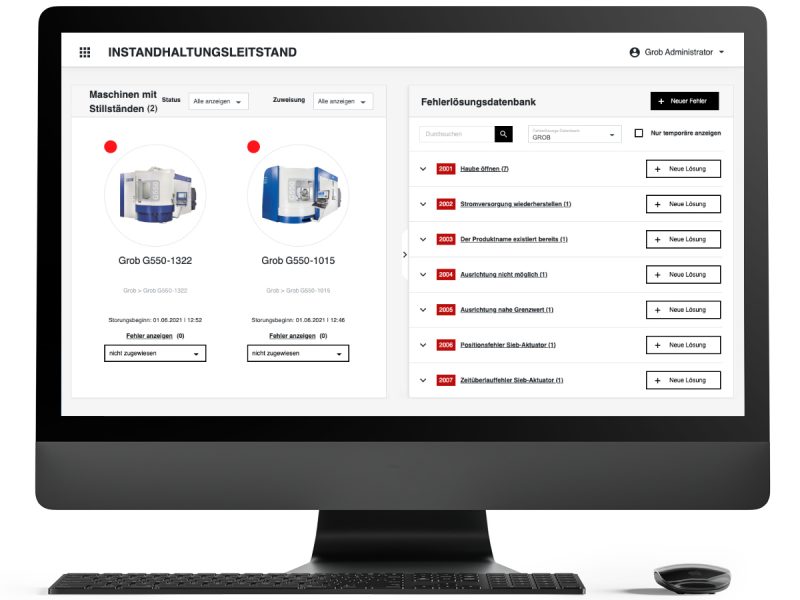

Asset Management & Equipment Efficiency

The digitalisation and networking of your company's key assets improves the scalability, efficiency and utilisation of your systems. We advise you on specific options and implement solutions that seamlessly complement your existing IT.

Predictive maintenance (AI)

The use of artificial intelligence can drastically reduce maintenance times and costs. We provide information about the possibilities and help with the implementation of intelligent solutions that can identify necessary maintenance for your products and prevent breakdowns.

Your advantages.

More efficiency with the ``digital twin``

A digital twin is the digitized image of real machines. The benefits of a digital twin cover the entire value chain, from the virtual product (design and simulation in a digital environment) to production (planning and simulation) to performance (analysis of equipment and production lines) and finally the real product.

Thanks to the digital twin, processes and optimizations can be achieved without a great deal of hardware effort. Data can be read out and visualized for analysis and systems can be networked through sensor connections, enabling a quick entry into the IIoT.

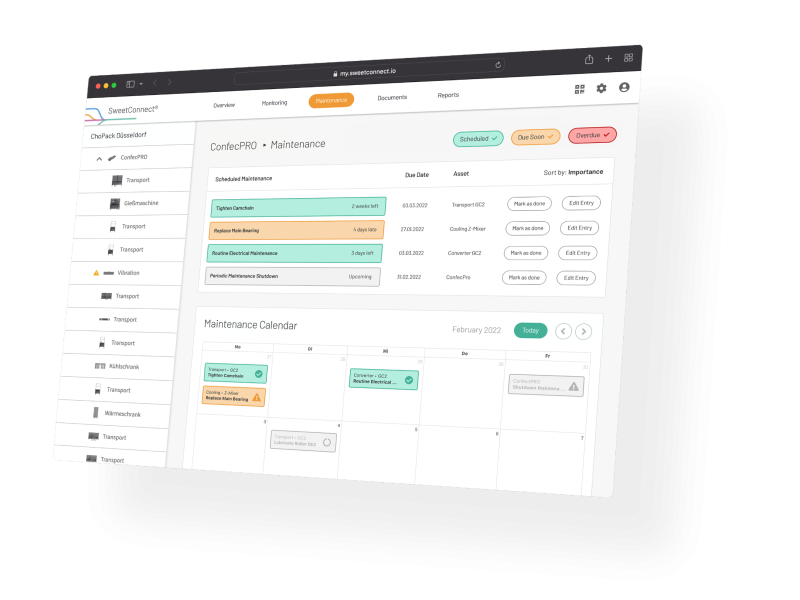

Fast entry into Industry 4.0 through ``Predictive Maintenance``

Predictive maintenance and A.I. (artificial intelligence) can be used to identify necessary machine maintenance and prevent breakdowns. As a result, maintenance times and costs are drastically reduced.

Machines and systems are becoming more intelligent and are able, for example, to independently communicate emerging faults and problems directly to different employee devices or to display complete maintenance timelines simply and clearly.

Predictive maintenance achieves particularly high optimization potential in cooperation with the aforementioned digital twin, i.e. supported simulations of the digital image of systems and machines.

Ensure the competitiveness of your company and take the networking of your machines to the next level.

Get in touch.

Do you have a project enquiry? Please do not hesitate to contact us - we will be happy to answer you promptly.