The fan and motor manufacturer ebm-papst Mulfingen GmbH & Co KG is modernizing its central "cockpit" software for order processing in production in cooperation with elunic AG. With its expertise in the implementation of cloud-enabled applications for mechanical engineering, elunic is supporting the company in the modernization and expansion of its applications based on shopfloor.io. The resulting applications will also enable the use of IoT and cloud scenarios - a major step in the flexible global rollout of Industry 4.0 functionalities.

In April 2021, ebm-papst and Munich-based elunic AG are launching a new software project for digitally supported production execution at ebm-papst's main site in Mulfingen. The basis for this is shopfloor.io, elunic's Industry 4.0 software kit for mechanical engineering. Before the project began, the technology leader in fans and motors already had powerful software. However, this was based on outdated technology. The aim of the project was to host the "360° hub around the production order" flexibly by using cloud-native technologies and to be able to deploy it quickly and efficiently globally. In addition, the scope of the modular software was to be expanded to include new "intelligent" application scenarios in the Industrial IoT (IIoT) and store floor environment.

Digitalization & central visualization for more efficiency on the store floor

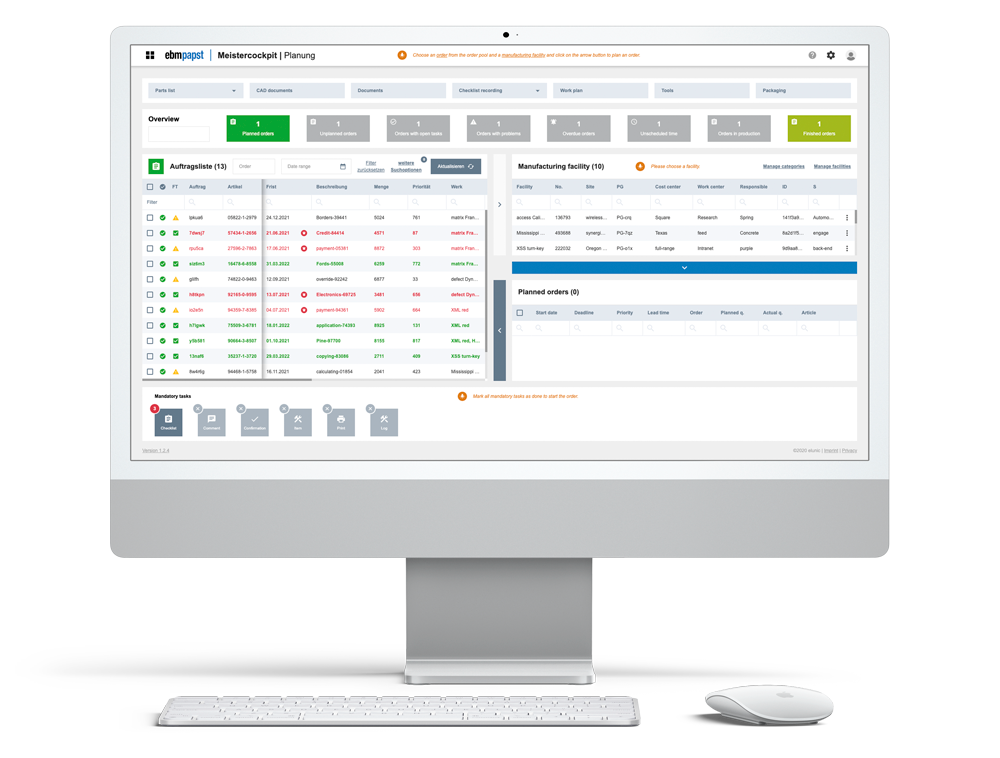

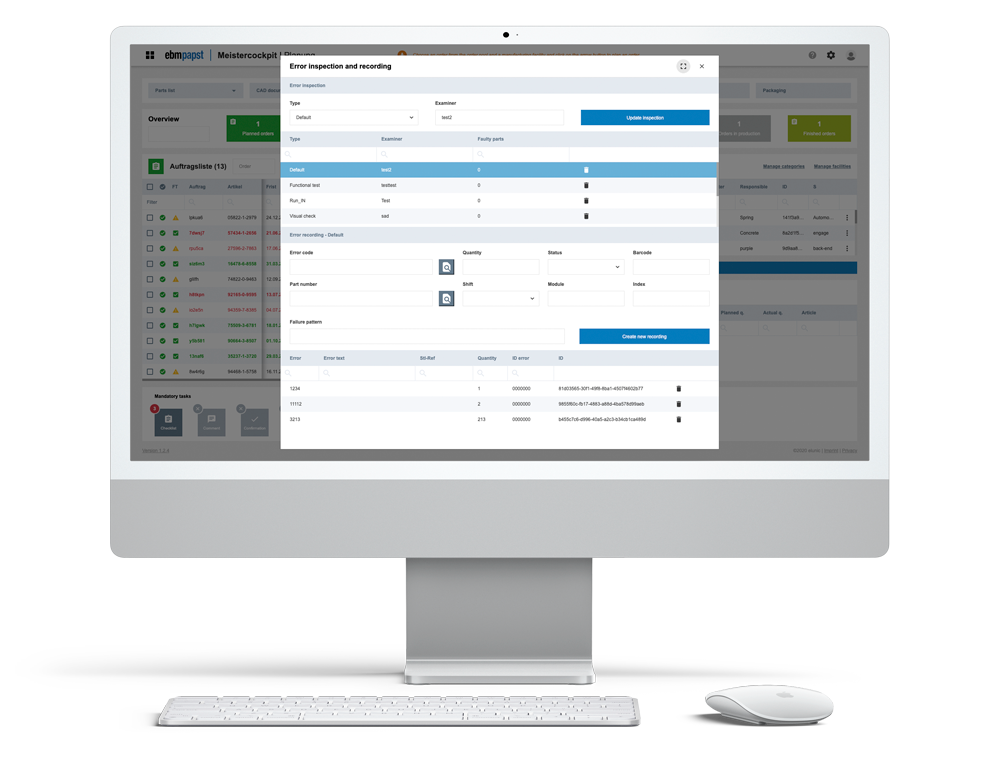

At ebm-papst, the new order hub is called "Meistercockpit", as it provides all those involved on the store floor, from the production employee to the industrial foreman, with all important information and application functions for the effective and efficient processing of production orders. Intuitive, status-guided functionalities are used to visualize the need for action and important information at a central location as required, providing employees with optimal digital support in carrying out their activities.

After a pilot phase at the headquarters in Mulfingen and at the production site in the USA, the plan is to extend the use of the newly designed solution to all production areas and global production sites in the further course of the project.

About ebm-papst

The ebm-papst Group, a family-owned company headquartered in Mulfingen, Baden-Württemberg, is the world's leading manufacturer of fans and drives. Since its foundation in 1963, the technology leader has been setting international market standards with its core competencies in motor technology, electronics, digitalization and aerodynamics. With over 20,000 products, ebm-papst offers tailor-made, energy-efficient and intelligent solutions for practically every requirement in ventilation and drive technology.

In the 2020/21 financial year, the hidden champion achieved a turnover of 2.129 billion euros and employs almost 15,000 people at 29 production sites (including in Germany, China and the USA) and 51 sales locations worldwide. ebm-papst sets the benchmark for fan and drive solutions in almost all industries, such as ventilation, air conditioning and refrigeration technology, heating technology, automotive, information technology, mechanical engineering and household appliances, intralogistics and medical technology.

Photos 1 & 2 © ebm-papst, Photos 3 - 5 © elunic

Further references

More about the reference project.