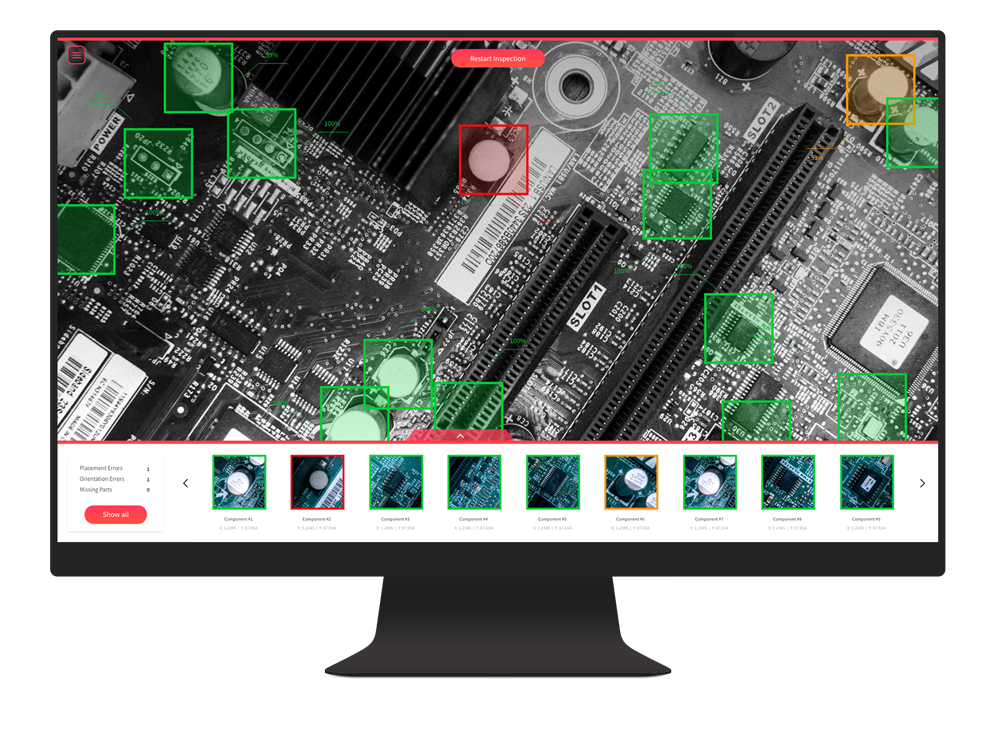

AI.SEE™ offers a solution for automatic inspection and defect detection in PCB production in order to automate the effort involved in defect detection during surface-mounting technology (SMT) and make it more efficient and reduce defect rates.

The precise inspection of printed circuit boards in production is crucial to ensure that the end products meet quality standards and function reliably. Quality inspection is often still carried out by production employees and is associated with a high level of manual effort and variance in inspection accuracy. Automatic optical inspection systems (AOI) such as AI.SEE™, on the other hand, use cameras and AI software to reliably identify soldering errors, placement errors, drilling or milling errors and damage to components.

Requirements

- Automated AI inspection for test benches or in-line integrations

- Reliable anomaly detection and classification

- Traceability of good and bad parts

- Intuitive operation to relieve employees

Solution

- Use of intelligent camera systems for high-resolution images to recognise the smallest features and microdefects

- State-of-the-art deep learning algorithms for reliable detection of defects such as soldering faults or damage

- Self-learning software to optimise recognition accuracy with every image captured

- Seamless integration into the production environment regardless of PCB type and cycle time

Can AI automate your PCB inspection?

AI.SEE™ uses artificial intelligence to enable manufacturers to carry out non-destructive, reliable and automated inspections of their products.

Thanks to deep learning algorithms, even the smallest defects on heterogeneous or reflective surfaces that are often overlooked by human inspectors can be found with consistently reliable quality, providing powerful insights that help improve quality and operational efficiency.

References

Find out more about the use case.