Quality assurance in the pressing plant

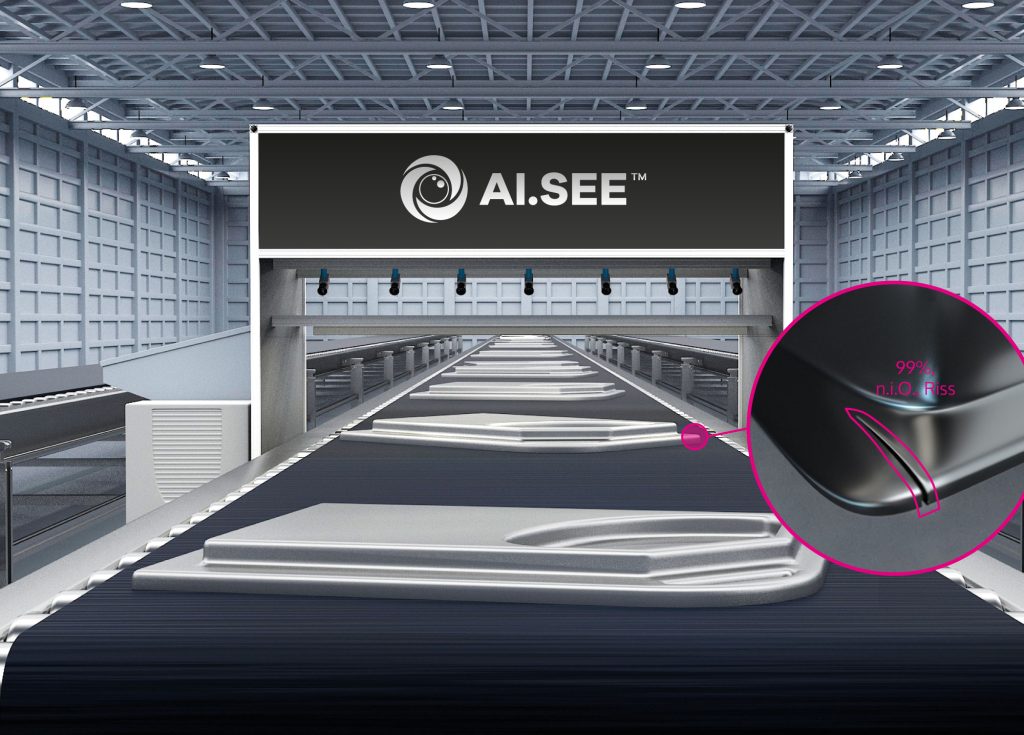

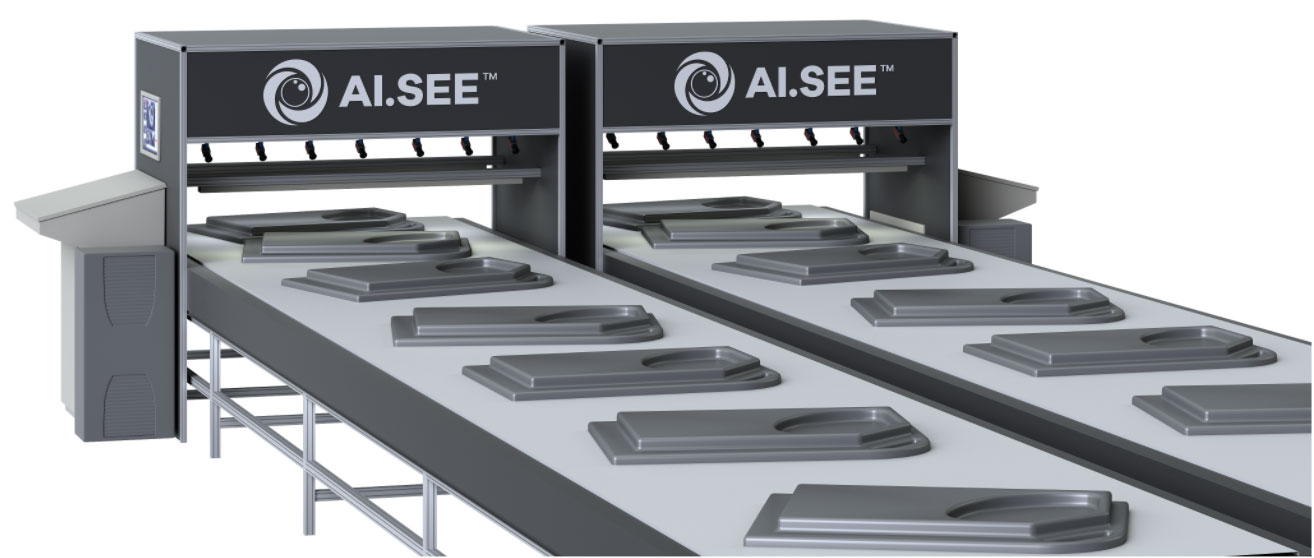

AI.SEE™ is a artificial intelligence based, visual Quality control and error detection system for producers in the Pressing plantwhich can be easily integrated into both new and existing outfeed conveyors thanks to its modular mounting technology.

Live recorded test images of components with typical errors of a pressing plant - like Cracks, Constrictions or Fractions - are already on the line and appropriate follow-up processes are triggered after the inspection.

Sheet metal parts are one of the most important components, especially in the automotive industry. They are used in Pressing plant of a production line through Reshaping prepared for further processing. A fully comprehensive Quality assurance procedures through Artificial intelligence can increase the efficiency of the industry and thus reduce costs.

AI.SEE™ from elunic offers the possibility to Pressing plant through a Retrofit again Competitive to make. Thanks to self-learning error detection through neural networks can also detect faults that are often overlooked by conventional solutions while maintaining consistently reliable quality. This means that the entire production quality is monitored centrally.

Conventional quality inspection in the industry

The industry standard in terms of Quality assurance are still today Quality inspectorwhich are characterised by Visual inspections check the production parts for defects on the outfeed conveyor. This Procedure to the Quality control Without digitalisation, it is therefore not possible to Complete testing because human error and the tight time frame are limitations.

Manufacturing processes in pressing plants

To optimise the Quality control on Sheet metal parts optimised in the best possible way, it is essential to know the applied Procedure in the manufacturing process. With the Production of sheet metal parts is dominated by the production process of forming. Consisting of Rollers, Open-die forging, Drop forging, Impact extrusion, Extrusion moulding, Deep drawing and Bending is that Reshaping a manufacturing process in which no material is added or removed. As a result, it retains its mass and cohesion.

However, before machine forming can take place in the Pressing plant the plastic material must be brought to the correct size. In the Cutting one pressing plant are realised by means of Cutting plants, Cutting systems or Lasering the raw materials are precisely prepared for further processing by forming.

Typical fault patterns in a pressing plant - necking, cracks, etc.

Conventional error characteristics are Cracks, Punching impressions, Constrictions, Fractions and Scratch. If, for example, the quality of the material is already inadequate on delivery, this can easily lead to faulty workpieces in the pressing plant. In addition to the general quality However, other factors play a role in production in addition to the materials. Start-up effects or Tolerances in the mould can lead to quality requirements not being met during the production of a component.

Digitalisation in the pressing shop of Industry 4.0

The introduction of advanced artificial intelligence in all parts of the manufacturing process are also available for the Modernisation the Quality assurance in the Pressing plant new possibilities. The limits of conventional quality control have been reached, particularly in terms of the time required for a visual inspection. If you want to achieve an efficient and One hundred per cent inspection of the production part, technical means cannot be dispensed with. But even these quickly reach their limits without artificial intelligence. Fixed algorithms of the Digitisationused for the analysis of Sensor data from quality-relevant characteristics are extremely complex and costly to develop. Nevertheless, they cannot be used flexibly, as their procedure must be precisely defined in advance and a consistent situation must be guaranteed by the producer.

Through Intelligent test procedures on the other hand, the Optical quality assurance an increase in the Efficiency and bring about a Complete quality control still In-Line guarantee. For a pressing plant, this means that the Press outlet every production part can be fully inspected for quality defects and thus a direct Error correction can take place.

Find out now with just a few questions whether your problem can also be solved by AI.SEE™.

Digitisation of a pressing plant with AI.SEE™ - Press plant retrofit

If you want your presses or even entire press lines moderniseTo remain competitive, this sounds like a costly endeavour at first glance. However, the latest technology for Digitisation in the Industry 4.0 the possibility of using a Retrofit of your pressing plant without replacing the entire hardware Productivity increases with lower production costs to achieve.

With the help of AI.SEE™, the quality assurance of your pressing plant can be fully modernised. It is not absolutely necessary to replace the entire pressing plant. After analysing the pressing plant, automation experts will find the right solution to optimise quality control. AI.SEE™ from elunic offers the option of relying on purely optical quality assurance thanks to AI. This means that the pressing plant does not have to be extensively rebuilt. The installation of standardised cameras is sufficient to guarantee quality assurance that can make decisions at the level of a trained quality management employee. The retrofit can also mean that your press shops can once again achieve longer maintenance intervals. These maintenance intervals often become a costly factor for systems that have been in use for a long time. Modernisation therefore not only achieves success in terms of efficiency and productivity, but also results in lower maintenance and servicing costs.

Functions and advantages of AI.SEE™

Further reference projects

References

Learn more.