In machining production today, tools and tool holders are mostly used without sensors. As a result, any quality defects caused by wear can usually only be detected after the machining process on the workpiece itself or through failures.

With iTENDO, Schunk has developed an intelligent tool holder with integrated sensors that can be used as a retrofit in existing machines. This enables the measurement of process stability and autonomous process optimization through real-time capable data communication, process analysis and parameter optimization.

In order to digitize, visualize, analyze and optimize the iTENDO data and the associated workflows, elunic was commissioned to contribute its experience in the IIoT area and the various IIoT platforms. elunic supports SCHUNK in the realization of the iTENDO application, from conception and design to development, operation and initial field tests. In order to achieve a quick start and the most efficient results possible, the elunic shopfloor.io-IIoT software modules were used in development, which provide a basis for white label IIoT solutions for machine manufacturers.

Added value through the Schunk iTendo platform

"elunic has enhanced our hardware and process expertise with their experience in developing IIoT software and architectures. By bringing together these different components and expertise, we were able to create a platform that will be used as the basis for further intelligent products and digital services from Schunk."

Dr. Martin May

iTendo apps and functions

iTendo application examples

Drill sinks

The iTENDO monitors compliance with the surface quality when countersinking holes. In this application, monitoring the countersinking process is used for quality and process control and to document function-critical features.

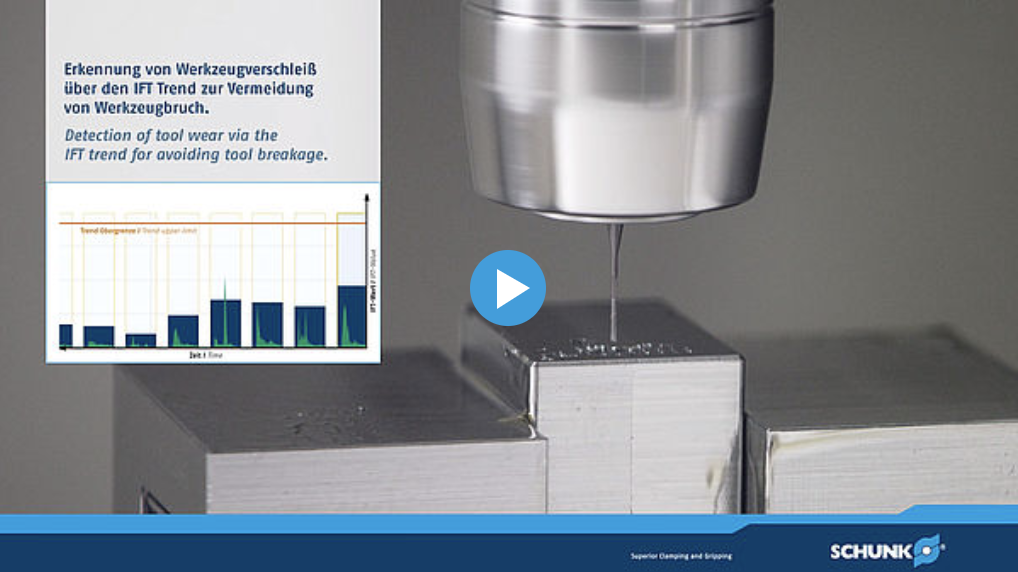

Drill wear detection

A drill with a diameter of < 0.9 mm is difficult to monitor due to its low cutting forces. The challenge is to detect wear (wear trend) and replace the tool before it breaks.

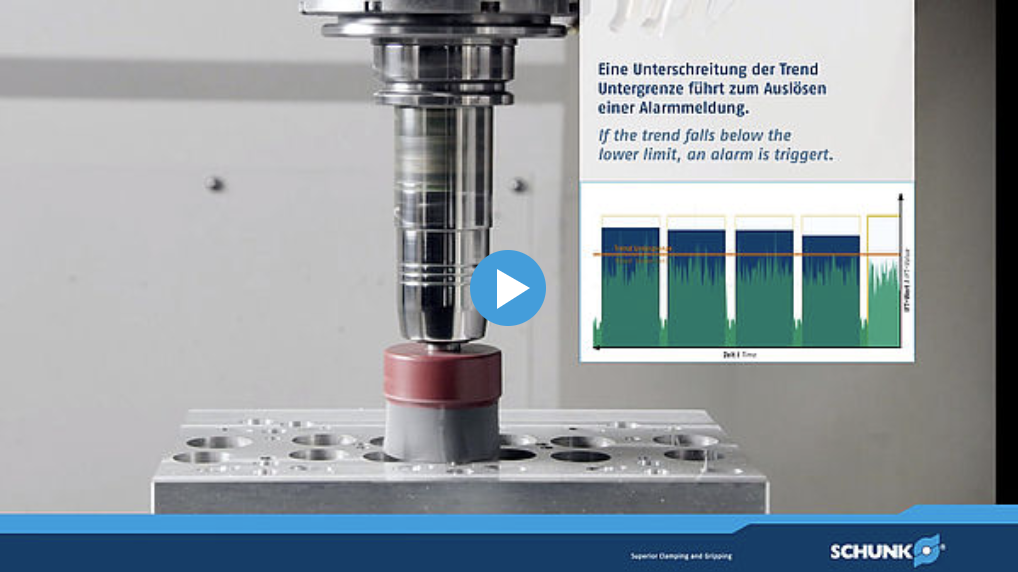

Automated adjustment of brushes

The edges on a workpiece surface are deburred using a brush operation. As the brush wears, the infeed must be readjusted. The iTENDO enables automatic adjustment.

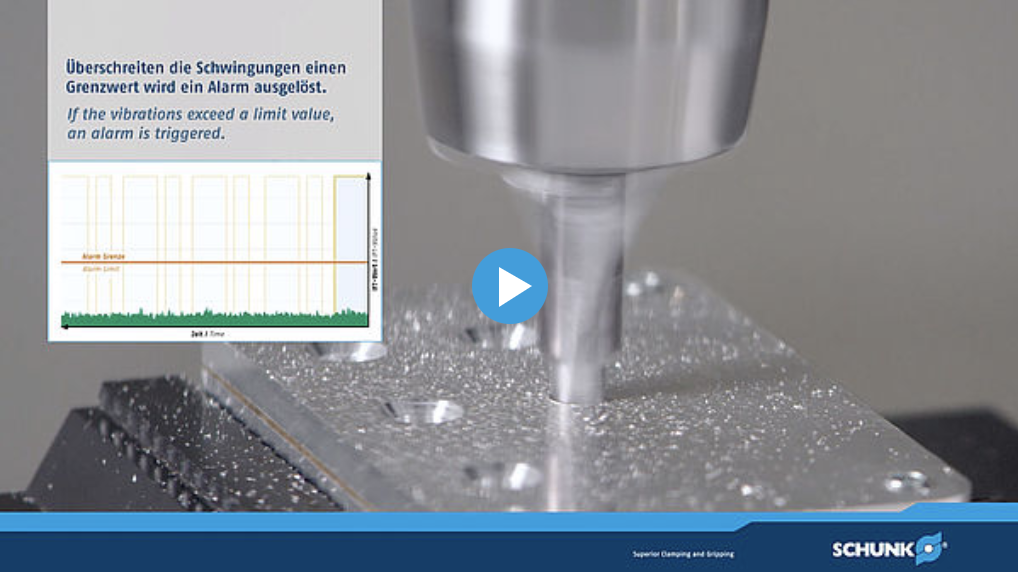

Adaptive vibration control

When milling a workpiece, the cutting conditions change depending on the changing workpiece contours. Chatter marks on the component can be avoided by adaptive control at the transition from different web widths.

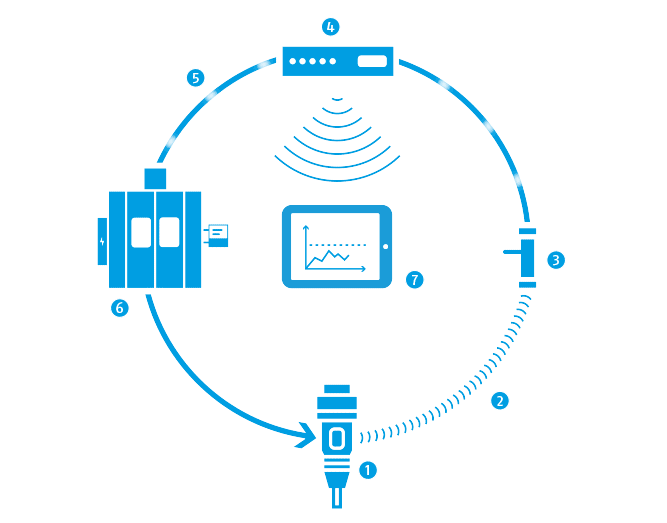

- iTENDO

- Wireless digital data transmission

- icotronic communication module in the engine room

- icotronic control unit

- Real-time communication

- Machine control

- Process control and customization of the app (OPC UA communication-capable)

Further references

More about the reference project.